Not Art and Science serve alone; Patience must in work be shown.

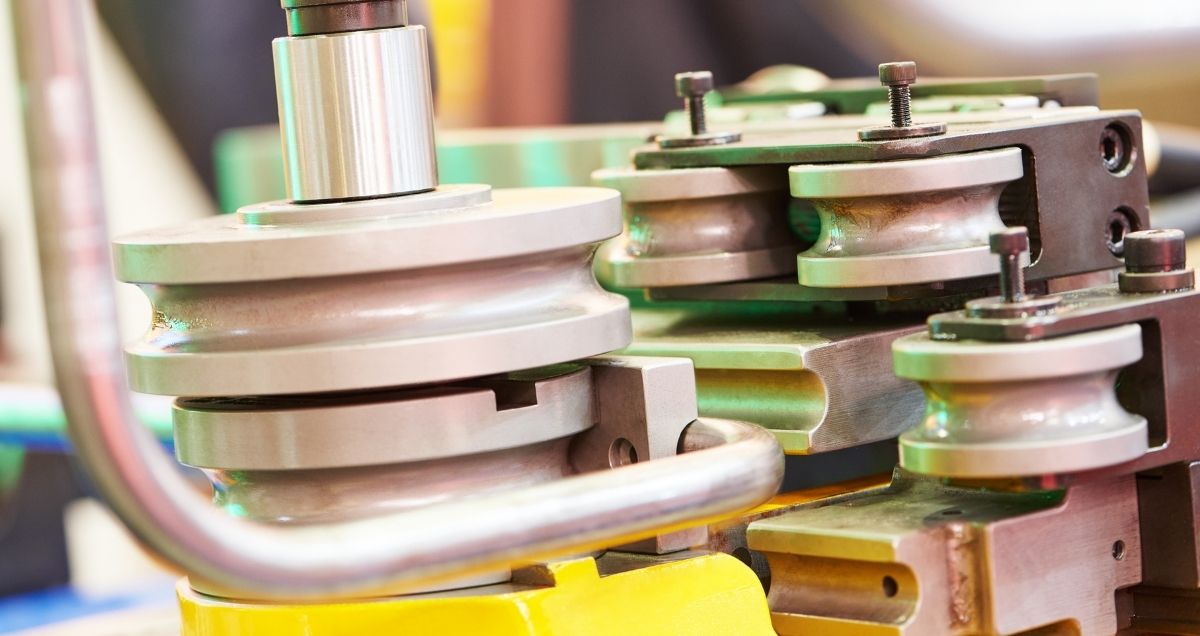

Well said. As an Australian machinery manufacturing owner, the first thing that comes into my mind after reading this is the Pipe Bending process. In my experience, bending pipes and tubes contain both science and arts. And with a bit of patience, you can get good quality results.

At the start, we went through a lot of trial and error, but ultimately, we succeeded. And it was necessary also because now my team and I know the preeminent things you should keep in your mind before the pipe bending process.

I am mentioning some knowledgeable points that will help you and your team command pipe and tube bending skills.

Key Considerations for Your Pipe Bending Process

Choose the angle for pipe bending wisely.

Generally, when you bend a tube or pipe to a certain degree, it will try to come back to its original shape and will get success with 3 to 4 degrees. Let’s say if you bend a pipe at 60 degrees, it will rebound a few degrees less than 60 degrees in some time. So, to get a perfect bend of 60 degrees, bend the pipe at 63 degrees. In this way, you will get a robust and elite desired angle of 60 degrees.

Use mandrel to avert flat toned bend.

Do you know about Flat toned Bend? A Flat toned bend contains a thinner tube wall, and the radius of the curve becomes tighter. The reason behind this bend is the outside wall of the pipe which is not thick enough to support itself in the bending process and ends up with collapses.

Ball and Plug mandrel can help you with a flat toned bend. You can put this inside the pipe and allow the tube during the bending process. Simple plug mandrels or segmented ball type mandrels can be used.

Use wiper dies to avert buckling and wrinkling.

Generally, as a manufacturer, we all face thin walls and minor bend radii issues while bending pipes and tubes. I have a solution for this problem. Try wiper die to prevent buckling and wrinkling in turning. You just need to place the wiper die in the back of the bend die using its tip at the tangent point. When the wiper dies encountering the friction force during the bending process, it gets operationally compatible with tubing material. This is how the use of wiper die material can lead to pleasing after unnumbered bending cycles.

Apply sufficient clamping pressure

Immense pressure in the pipe bending process plays an important role. Specifically, the tube can slip in the clamp die in an old set of tools if you put little pressure. As a result, you can get unpleasant deformations like kinks and wrinkles inside of the bend and will get a useless workpiece. Therefore, it is essential to put much pressure on pipe bending tools to prevent wrinkles.

Final Checks & Setup for Tube Bending

We understand the need for robust and seamless machinery. That is why we offer you.

- Solid Wiper Dies

- Tip Style Wiper Dies

- Mandrel Links and Balls

- MACKMA and YLM pipe bending machines

Check our website and contact us for more details.