What are Press Brake Tools ?

A press brake tooling is used for bending sheet and plate material that is already formed through pre-punched materials. In the past, engineers needed to operate it manually, but now we have automated specific models. This device is widely used in various industries such as automobile, aircraft manufacturing, light industry, shipbuilding, containers, elevators, railway vehicles, etc.

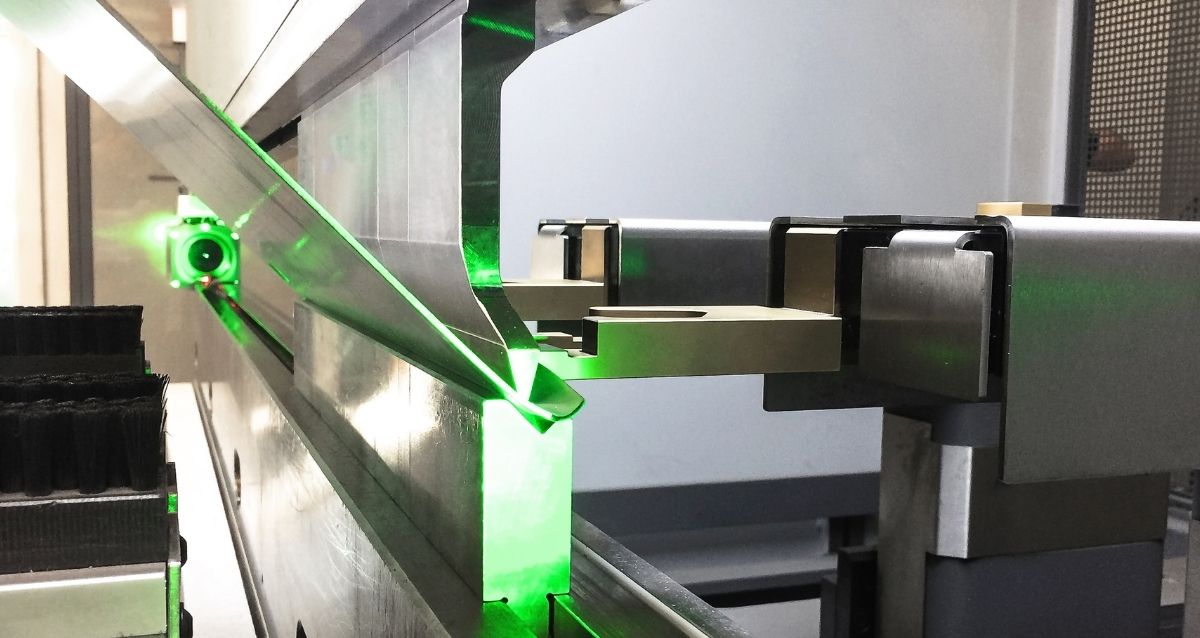

The structure of the Press Brake Machine

- Press brake machine is a free-standing CNC press, integral welding processing structure. The working range of the machine is as extensive as it can be. The maximum length of the mainframe can go up to 6000mm or so.

- The mechanical outline structure of the Press Brake Machine mainly refers to its upper and lower parts and working mechanism. But also it relates to its movable slider, which has become a “focus” in recent years. Because of its importance in the production process and function performance.

- Press brake machine hydraulic system has a super simple configuration. In this way you can reduce the pre-installation of the pipeline process to one-fifth. And the maintenance work will become mobile. It is reliable, safe and beautiful.

Types of Press Brake Tooling

There are essentially two categories of press brakes.

Electronic Press Brakes

An electric press brake has a motor directly linked to the bending mechanism rather than an operator having to switch it on and off. This allows for greater efficiency, mainly when operating a press brake that can make many bends in a single round.

Hydraulic Press Brakes

Hydraulic press brakes rely on oil-filled hydraulic cylinders to operate. They are the most potent mechanical press brakes and are often preferred for more extensive jobs. Because they can quickly cycle even large pieces of material. However, it is worth noting that this machine also tends to use more electricity and oil. And it is less energy efficient.

How Press Brake Tooling works

Press brake systems are a great way to cut metal. They use rollers and a series of rollers to generate a horizontal force that is about the same as the sheet metal or plate material during manufacture.

- The press brake system uses a vacuum to pull on the sheet metal to create multiple points of contact with the metal stock. It helps prevent warping.

- A press brake system has a frame supporting the roller, moving side to side as the roller rotates.

- A power source drives the rollers and causes them to turn. The material to be bent is fed through the machine.

- The pressure on the fuselage is released, causing it to flatten out. And as a result, the material automatically turns into the desired shape.

How to choose Press Brake Tooling Machine

A small metal bending machine will do just fine if you’re a beginner. However, if you are looking for a metal press that can handle medium-sized and even high-end metal bending jobs, then you’re going to want to look at more giant metal bending machines. But before you start keep the below points in your mind.

Base size

The base size of your press brake is essential to consider. For example, the bed length between the two arms is known as the “base length.” Typically, a smaller base is better for working with thinner sheet metal up to 22 gauge (0.036 inches).

Choose specific model

The primary purpose of purchasing a specific model of sheet metal press is to meet your demand in terms of sheet dimensions, thickness, and material grade. Moreover, you need to pay attention to the material you are using the press brake tool and buy accordingly.

Affordability and Quality check

Press brake tooling price is essential. Because it may decide how long your press brakes will be functional before requiring maintenance or a complete overhaul. Sometimes old tooling also may cause more damage to the structure of your press brake. So it’s good to go with newly manufactured tooling, which can reduce your maintenance costs in the future.

Strength and Power of machinery

Press brake tool’s strength is essential to check before buying. Because when a master would say something like “the quality does not match the price”, it will hurt your market presence. Moreover, It is a matter of decisive factor on this product, and Different quality tools have different price tags!

Final Note

Ultimately, purchasing press brake tooling for your business is an investment in your company’s future. There are other bending sheet and plate materials options, but very few of them have the speed and power of a press brake. Therefore, having the proper press brake tooling for your manufacturing business will allow you to achieve its maximum potential.

Delahenty Machinery – Get robust Press Brake Tooling

Delahenty Machinery is the leading provider of press brake tooling in Australia by offering the highest quality, durable and reliable products on the market. When you need high precision, entry-level machining, and material handling at a cost-effective price, there’s no better place to go. Contact us for more details.