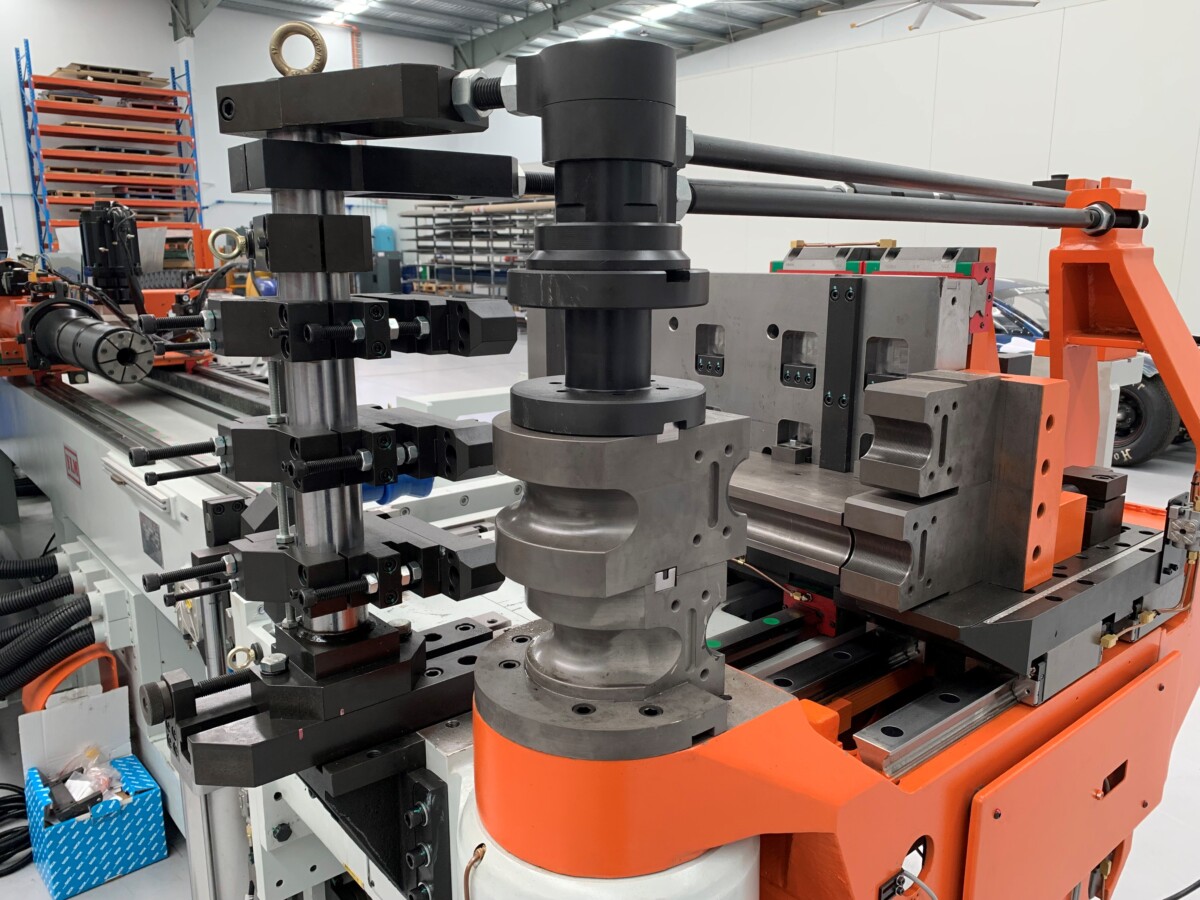

Delahenty Machinery, a trusted name in Australian manufacturing, has become a key player in designing, producing, and supplying high-quality bending tooling solutions for a variety of industries. With decades of experience, the company specialises in producing precision tooling components for tube bending and end forming applications.

Need a tool set built quickly? Our engineers and design team are ready to help.

So, why wait? Call (03) 9800-1544 and take your tube bending processes to new heights of precision.

High-Quality Tooling Solutions

At the core of every forming application, tooling plays a vital role, and Delahenty Machinery has dedicated itself to providing only the best. The company designs and manufactures complete tube bending and end forming tool sets, ensuring customers receive top-notch tools and rapid turnaround times. Their product offerings include:

Bend Tooling

End Form Tooling

Mandrel Links and Balls

One piece and Tip Type Wiper Die

Ball & Plug Mandrels

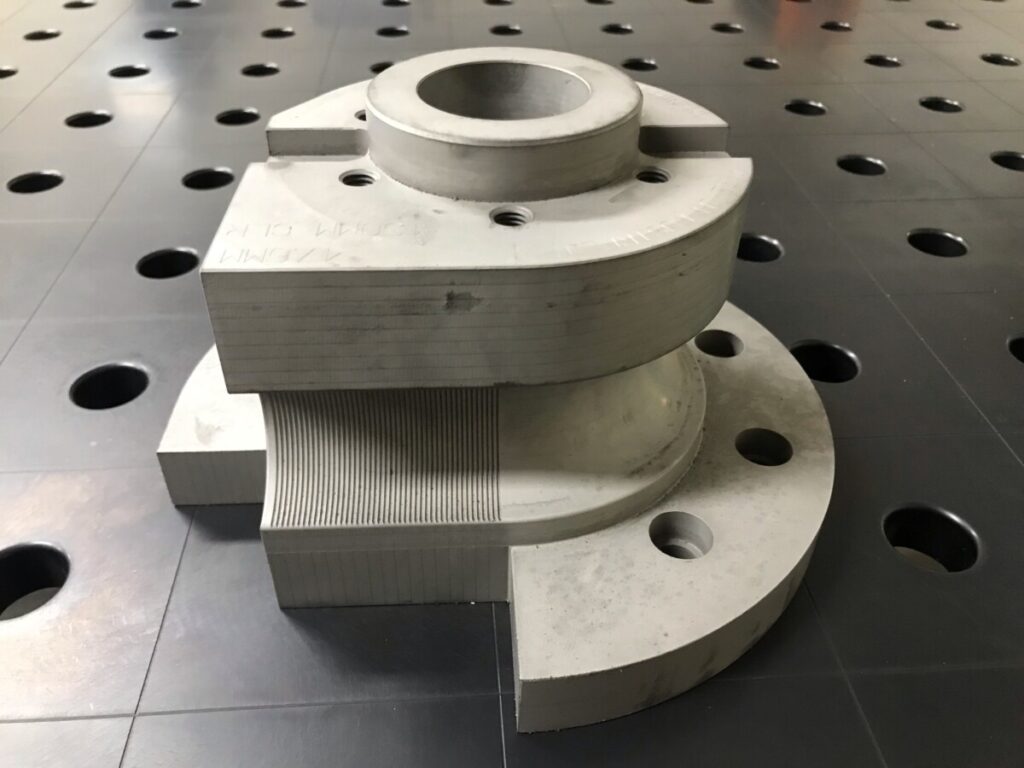

Advanced Mandrel Options

Delahenty Machinery offers an extensive selection of mandrels for various applications, made from both tool steel and aluminium bronze. Some of the available types include:

Close Pitch Mandrels for thin-wall and tight-radius bends

Chain Style Mandrels

Plug and Spoon Mandrels

Square, Rectangle, and Oval Mandrels

Plastic, Tool Steel, and Aluminium Bronze Mandrels

Mandrels for Extrusion Bending

Custom Body Lengths and Thread Options

Wiper Dies and Re-Cut Services

The company also manufactures a wide range of solid wiper dies, including both tool steel and aluminium bronze variants, with mounting options suitable for all manufacturers. Their re-cut service offers fast turnaround times for:

Solid wiper dies

Tip type wiper dies

Re-boring and re-cutting of wiper dies

Comprehensive Tooling Sets

Delahenty Machinery excels in designing and manufacturing complete bending tooling sets, tailored to customer needs. These include:

Full Bend Tooling Sets

Interlock Tooling

Square, Rectangle, and Oval Tooling

Extrusion Tooling

Empty Bend Tooling

Controlled Wrinkle Tooling

Split Tooling Designs

Collets

Twin Head and Press Bend Tooling

Solid and Flat Bar Tooling

Quick Change Tooling Designs

Section Roll Tooling

Delahenty Machinery also offers specialised roller solutions for profile roll forming, available in both steel and nylon. These rollers are designed and hardened to handle materials such as steel, aluminium, and stainless steel.

Expert Tooling Design & Development

All tooling is designed in-house in Australia using 3D CAD software, ensuring precise and efficient production. Delahenty Machinery is committed to meeting both production and budget requirements, offering a range of design services, such as:

- 3D CAD Tooling Design

- Tooling Prints and Quick Replacement Manufacturing

- Ongoing Tool R&D and Bent Part Simulation

- Tool Steel Selection and Price Estimation

- Reverse Engineering of Tooling

With an unwavering focus on quality, innovation, and customer satisfaction, Delahenty Machinery remains a leader in the Australian tooling industry, offering customised solutions for even the most complex forming and bending applications