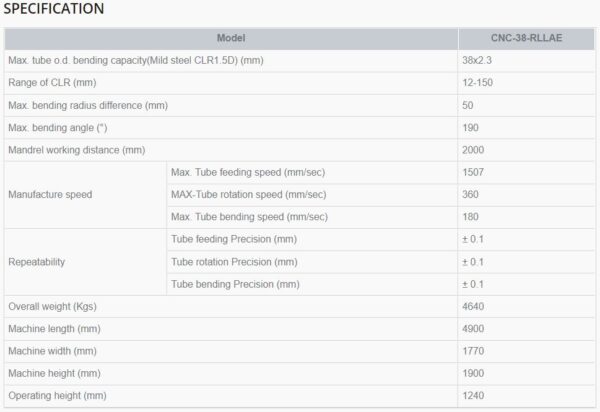

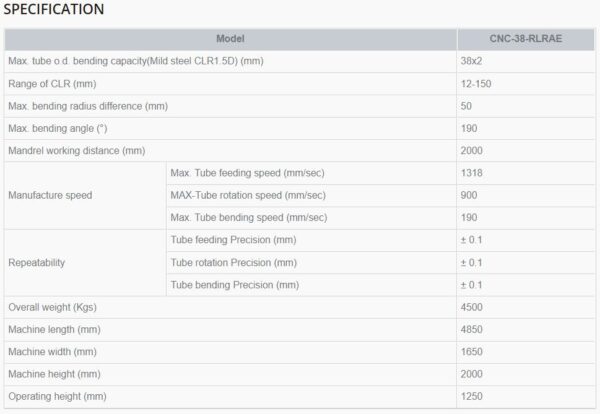

YLM – Right & Left Tube Bender – CNC38-RLLAE & CNC-38RLRAE

Specifications

| Make | YLM |

|---|---|

| Model | CNC38-RLLAE |

Description

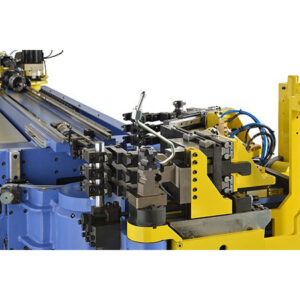

YLM – Right & Left Tube Bender – CNC38-RLLAE & CNC-38RLRAE

The YLM CNC38-RLLAE & CNC-38RLRAE are fully electric CNC tube benders designed for both left-hand and right-hand bending functions:

- Symmetrical Tube Bending:

- Practical models suitable for symmetrical tubes, such as furniture production, hydraulic-oil tubing lines, and HVAC tubing.

- Ideal for fluid systems in automobiles.

- Bending Capacity:

- Max tube outer diameter bending capacity (Mild steel CLR1.5D): 38×2.3 mm.

- Range of CLR (centerline radius): 12-150 mm.

- Bending Precision:

- High repeatability with precision of ±0.05 mm for tube feeding, rotation, and bending.

- Ensures consistent and accurate results.

- Tube Feeding Speed:

- Max tube feeding speed: 1507 mm/sec.

- Efficient material handling during production.

- Tube Rotation Speed:

- Max tube rotation speed: 360 mm/sec.

- Smooth and controlled rotation for precise bending.

- Tube Bending Speed:

- Max tube bending speed: 180 mm/sec.

- Rapid and efficient bending process.

- Mandrel Working Distance:

- Ample working distance of 2000 mm for mandrel support.

- Safety and Compliance:

- Integral cutting area protections with automatic opening and closing.

- Complies with CE safety regulations.

- IP 55 protection.

- Servo Motor:

- Equipped with YASKAWA servo motors for reliable performance.

- Industry 4.0 Ready:

- Meets Industry 4.0 requirements.

- Ethernet, Wi-Fi, and teleassistance capabilities.