YLM – CNC Hybrid Tube Bending Machine – CNC-220S1

Specifications

| Make | YLM |

|---|---|

| Model | CNC-220S1 |

Description

YLM – CNC Hybrid Tube Bending Machine – CNC-220S1

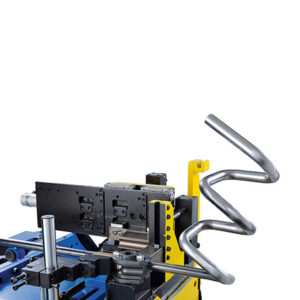

This cutting-edge machine combines hydraulic and electric technologies for precise and efficient tube bending:

The YLM CNC-220S1 is a robust tube bending machine designed for various industries, including boiler manufacturing, heavy transportation vehicles, chemical engineering, power plants, and marine applications. Its hybrid design combines the advantages of hydraulic and electric systems, resulting in improved performance and longevity.

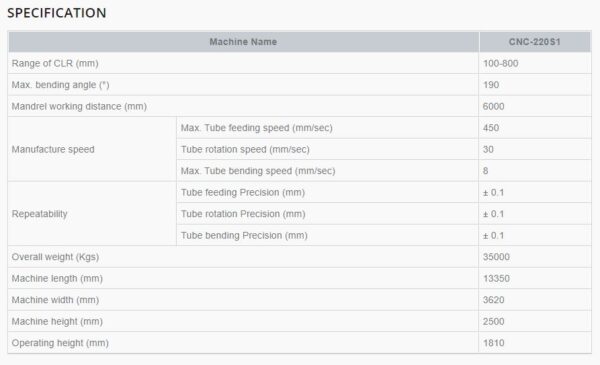

Specifications

- Max. Tube Outer Diameter Bending Capacity (Mild Steel CLR1.5D): 220 mm x 6 mm

- Range of CLR (Center Line Radius): 100-800 mm

- Max. Bending Radius Difference: Not specified

- Max. Bending Angle: 190°

- Mandrel Working Distance: 6000 mm

- Manufacture Speed:

- Max. Tube Feeding Speed: 450 mm/sec

- Max. Tube Rotation Speed: 71.2 mm/sec

- Max. Tube Bending Speed: 8 mm/sec

- Repeatability:

- Tube Feeding Precision: ±0.05 mm

- Tube Rotation Precision: ±0.05 mm

- Tube Bending Precision: ±0.1 mm

- Overall Weight: 35,000 kg

- Machine Dimensions:

- Length: 13,350 mm

- Width: 3,620 mm

- Height: 2,500 mm

- Operating Height: 1,810 mm

Features

- Hybrid Technology: The CNC-220S1 combines hydraulic valves and integrated circuits to control bending motion individually, enhancing the service life of hydraulic components.

- Digital Flow Regulation Valve: The large bending machine features a manually adjusted digital flow regulation valve, allowing precise control over bending speed.

Applications

The CNC-220S1 is suitable for bending tubes used in:

- Boiler manufacturing

- Heavy transportation vehicles

- Chemical engineering

- Power plants

- Marine industry