YLM – CNC Hybrid Tube Bending Machine – CNC-16AS2

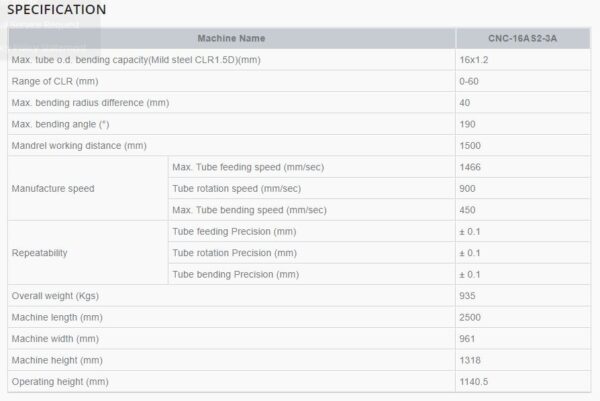

Specifications

| Make | YLM |

|---|---|

| Model | CNC-16AS2 |

Description

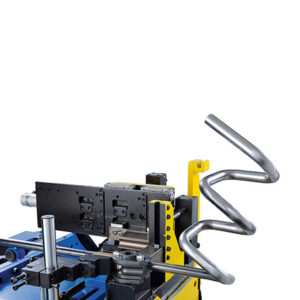

The YLM CNC-16AS2 Hybrid Tube Bending Machine represents the pinnacle of tube bending technology, offering a sophisticated blend of hydraulic and servo-driven systems. Designed for high-performance and versatility, this machine is ideal for applications requiring precision, flexibility, and reliability.

Features:

- Multi Axis Servo-Motor Control:

- Versatile Bending Capabilities: The CNC-16AS2 features advanced 4/5 axes servo-motor control, enabling complex bending operations with high precision. This allows for intricate and multi-dimensional bends that are critical for high-quality fabrication.

- Hydraulic Valve and Integrated Circuit Control:

- Enhanced Durability: The machine employs hydraulic valves and integrated circuits to control bending motions individually. This approach extends the service life of hydraulic components by reducing wear and tear, leading to long-term reliability and lower maintenance costs.

- Manual Digital Flow Regulation Valve:

- Precise Speed Control: Large bending machines are equipped with a manually adjustable digital flow regulation valve. This feature allows for precise control over the bending speed, accommodating various material properties and bending requirements.

- High Accuracy Servo Drive:

- Exceptional Bending Precision: The servo drive system ensures high accuracy in bending positioning. This precision results in high-quality bends and consistent repeatability, essential for achieving exact specifications and high standards in finished products.

- 3D Simulation of Bending Process:

- Visual Planning and Optimization: The machine includes a 3D simulation feature that allows operators to visualize and optimize the bending process before actual production. This capability aids in reducing errors, optimizing setups, and enhancing overall efficiency.

- CNC Automatic Tube Bending Machine:

- Automated Efficiency: As a CNC automatic tube bending machine, the CNC-16AS2 offers automated operation, streamlining the bending process and reducing manual intervention. This automation increases productivity and ensures consistent results.

Benefits:

- High Precision and Quality:

- The Multi Axis servo-motor control and high-accuracy servo drive deliver precise bending positions and high-quality bends. This ensures that each tube meets exact specifications and improves the overall quality of the finished products.

- Increased Durability and Reduced Maintenance:

- The use of hydraulic valves and integrated circuits to control bending motions individually extends the service life of hydraulic components. This results in reduced maintenance needs and lower long-term operational costs.

- Versatile and Flexible Operation:

- With the ability to perform complex bends and adjustments, the CNC-16AS2 is highly versatile. The manual digital flow regulation valve adds flexibility by allowing operators to control bending speeds according to different material and design requirements.

- Efficient Production:

- The CNC automation and 3D simulation features enhance production efficiency by minimizing setup times, reducing errors, and allowing for pre-optimization of bending processes. This leads to faster production cycles and higher throughput.

- Enhanced Visual Planning:

- The 3D simulation capability provides a clear visual representation of the bending process, helping to identify potential issues and optimize setups before actual production. This reduces the likelihood of costly errors and material wastage.

- Streamlined Operation:

- Automated functions reduce the need for manual intervention, leading to smoother operations and increased consistency in bending results. This also simplifies the training process for operators and improves overall workflow efficiency.

The YLM CNC-16AS2 Hybrid Tube Bending Machine is designed to elevate your tube bending operations with unparalleled precision, durability, and efficiency. Whether you’re working on intricate designs or high-volume production, this machine delivers the performance and reliability needed to achieve exceptional results.