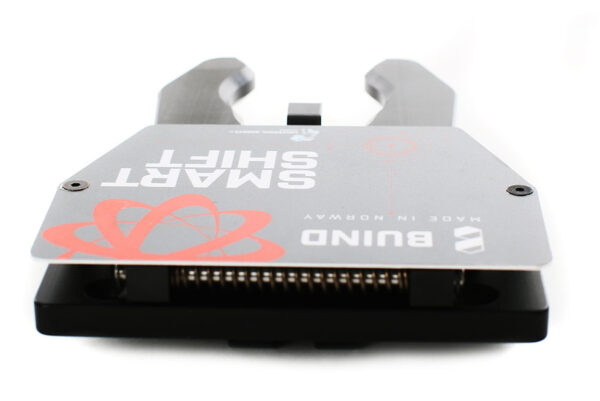

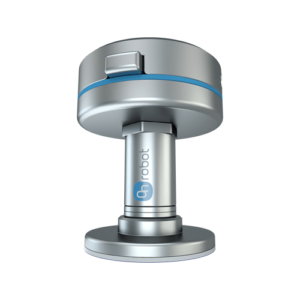

Smartshift Robotics – Automatic Pneumatic Clutch Range

Specifications

| Make | Smartshift Robotics |

|---|

Description

The Smartshift Automatic Pneumatic Tool Changer is a versatile solution for applications where tool changing is essential:

- Automatic Tool Change:

- Seamlessly switch between tools without stopping production.

- Enables mechanical, pneumatic, and optional electric connections.

- Upgrade to electrical connection with the SMARTSHIFT cable electric connector M8.

- Precision and Speed:

- Works at high speed with excellent stiffness.

- Accurate to within five hundredths of a millimeter in all directions and angles.

- Flexible Deployment:

- Easily deploy and redeploy due to smart mechanical design.

- Universal compatibility for lightweight industrial and collaborative robots.

- Payload Handling:

- Supports a payload of up to 50 kg.

- Ideal for various tasks across different production lines.

- Applications:

- Assembly: Improve product quality and efficiency in screw driving, mounting, and positioning processes.

- Palletising / Packing: Quickly switch tools for sorting, packaging, labeling, and palletizing.

- Machine Tending: Consistently follow precise processes in CNC, injection molding, and metal casting.

Remember, the SMARTSHIFT system enhances productivity by minimising downtime and ensuring non-stop operation.