RICO – Press Brakes – PRCN C-LINE

Specifications

| Make | RICO |

|---|

Description

Press Brakes – PRCN C-LINE

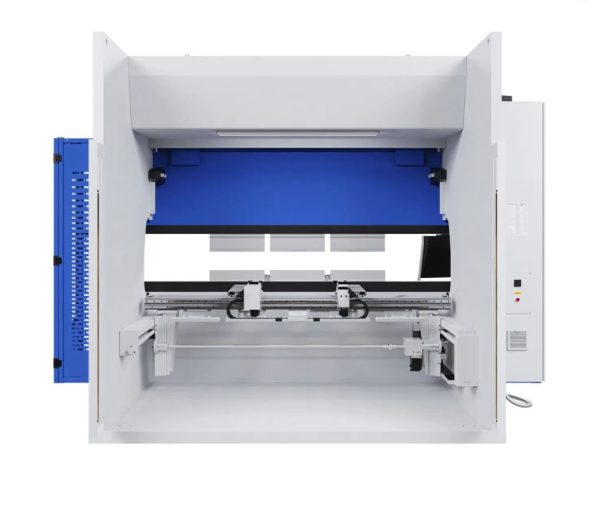

PRCN press brakes can be used in any type of company and any kind of work, from the bending of the simplest parts, up to mass production of complex parts with tight tolerances. It is the ideal solution to achieve a higher level of competitiveness, precision and safety in sheet metal bending, by drastically increasing profitability and productivity.

Productivity

- Automatic calculation of angle, force and back gauge axis.

- User-friendly control

- High performances

Versatility

- Swaybend system (RICO)

- Configuration to the customer

Accuracy

- H-Box frame (RICO)

- Structural compensation system

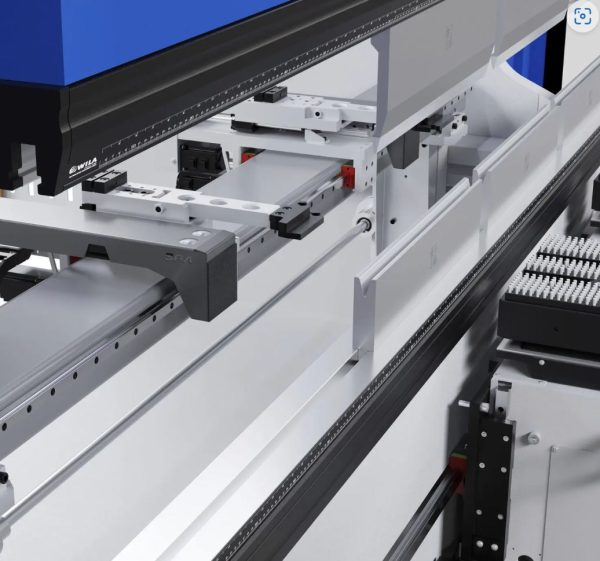

- Servo-motorized axis

- Proporcional hydraulics

Safety

- Machines with directive CE 2006/95 CE

- Lazer safety device

Reliability

- RICO has a strict policy for the choice of its components, on the basis of an extensive experience acquired over decades.

- All components are certified in accordance with European standards and their main sources are Germany, USA, Holland, Italy and Switzerland. All structural parts are calculated by the finite element method and only high quality steel S275 and S355 JR namely J2 (+ N) is used.

H-Box Frame: Precision guaranteed

- The cylinders are placed inside a H-shaped mono-block upper frame with a smaller distance between them. This allows for the structural deformation to be reduced in 60% and for a minimal and more homogeneous distribution of the physical forces, even under demanding (stressful) circumstances;

- The performance in off-center and multi-station bending is outstanding.

SwayBend System: More versatility

- Conical bending with sensible angle differences between the extremities of the part to bend is now possible because of the fixing method of the upper beam to the cylinder rods trough special caps and of their special guiding system.

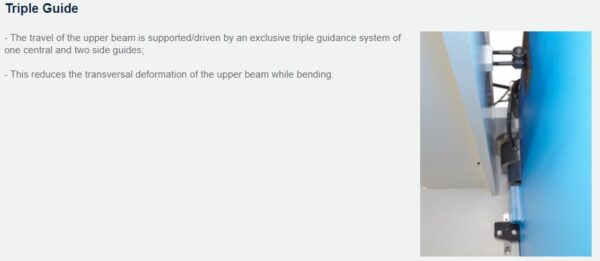

Triple Guide

- The travel of the upper beam is supported/driven by an exclusive triple guidance system of one central and two side guides;

- This reduces the transversal deformation of the upper beam while bending.

A StandBy Function: Effective saving

- Energy saving mode is activated whenever the machine does not perform any bend over a period of 5 minutes, even in programming mode. ?

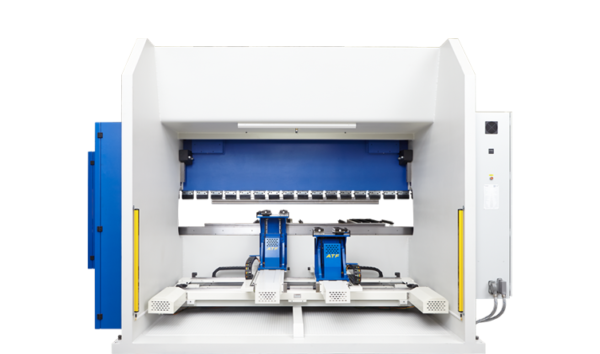

PRCN Cell

- PRCN Press Brake allows integration of robotic cells that are developed to suit each project.

Characteristics

- Operation: hydraulic

- Control: CNC

- Other characteristics: precision, high-speed, high-performance

- Press force: Max.: 500 tf, Min.: 250 tf

- Folding length: Max.: 4 m (13’01” ), Min.: 3 m (9’10” )

- Made In: Portugal