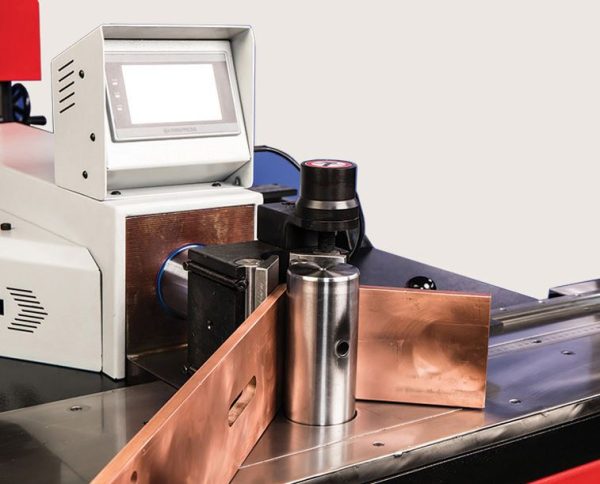

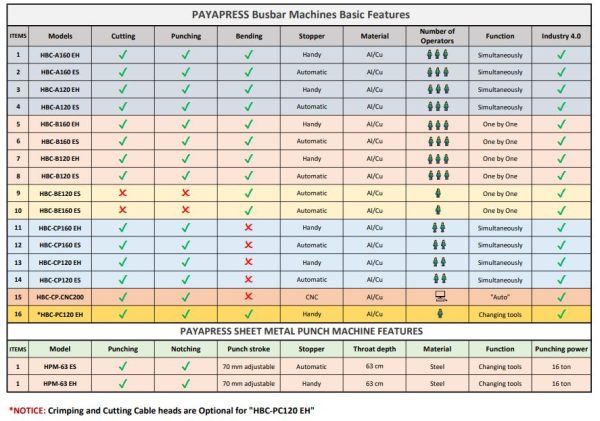

PAYAPRESS – HBC-A120 ES/EH – Busbar Bending, Punching and Cutting Machine

Specifications

| Make | PAYAPRESS |

|---|---|

| Model | HBC-A120 ES/EH |

Description

PAYAPRESS – HBC-A120 ES/EH – Busbar Bending, Punching and Cutting Machine

3 in 1 machines: which means busbars could be fully processed (Bending, Cutting, Punching) on these devices.

The most important feature of this series of PAYAPRESS busbar machines is that 3 operators can work on all three stations simultaneously without interrupting the other one and the reason is that this series of machines are equipped with 3 power packs.

The difference between Model: HBC-A120 and HBC-A160 is just the maximum size of busbar that can be processed, A120 is capable of process busbars up to 120*12 mm while the A160 can do more and the maximum busbar size is up to 160*15 mm.

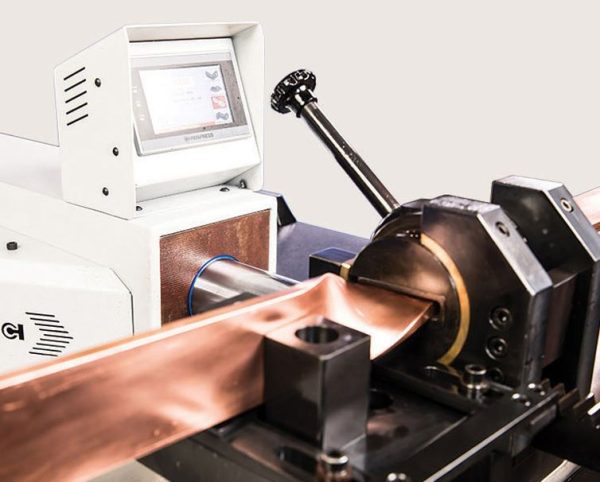

Bender

- Bender controller equipped with spring back compensation system.

- Digital angle indicator leads to perfect bending result.

- Rotatable plates prevent fractions in busbar surface

Step mold (Optional)

- To create too closed bends in one stroke

- could be designed in different sizes by order

Edge bending mold (optional)

- To bend busbars from edge side

- Busbar size limit: 40 × 10 mm

Up to 90 degree and 50× 10 mm

Up to 45 degree

Twist bending mold (Optional)

– To twist busbars for special purpose

– Busbar size limits: 60 × 10 mm

Up to 90 degrees.

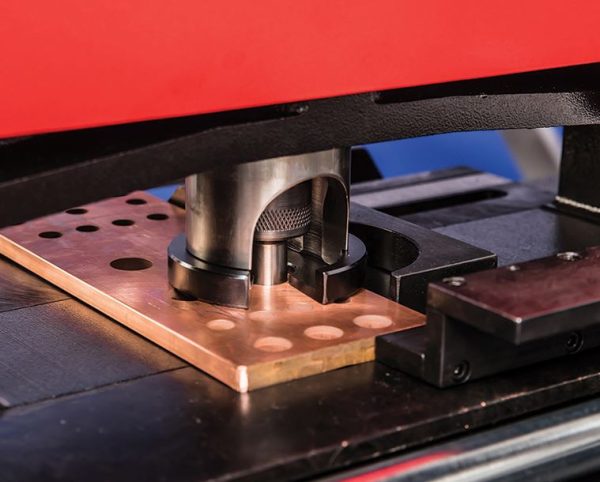

Puncher

- Laser pointer helps to find the center of holes easily

- Easy and changeable dies

- Movable stripper plate prevents fraction in dies

- Double acting hydraulic system prevents sticking dies in busbar after punching

Guides could be moved up to center of dies

Rollers at two side of puncher for ease of busbar movement

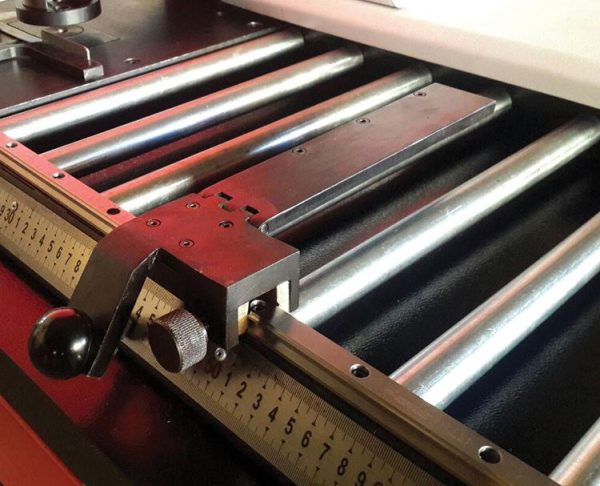

Programmable Length Stopper cause high accuracy in positioning of holes (Optional)

- Could be programmed in absolute and incremental positions

- Programmable for 20 positions

Handy Length stopper with high accuracy adjustment

Circle dies from M6 up to M18

Oval and rectangle dies (Optional)

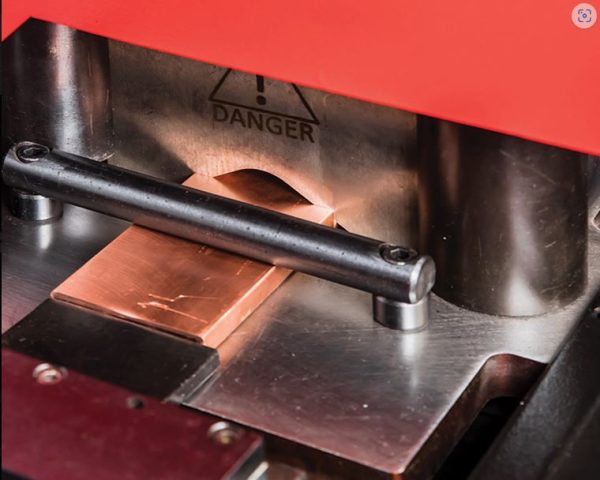

Cutter

- Precise cutting with high quality

- Perfect finishing after cutting

- Center oriented guide leads to the best result

- Programmable Length Stopper cause high accuracy in positioning of cuts (Optional)

- Could be programmed in absolute and incremental positions

- Programmable for 20 positions

- Rollers at two sides of cutter for ease of busbar movement

- Handy Length Stopper with high accuracy adjustment