MACKMA – BTT Series – Metal Chip Briquetting Machines

Specifications

| Make | MACKMA |

|---|---|

| Model | BTT Series – Metal Chip Briquetting Machines |

Description

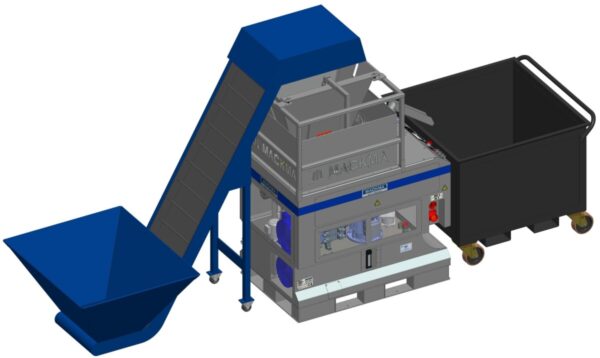

The Mackma briquetting machine range offers a versatile and compact solution for compressing metal shavings and recovering processing oil or emulsified coolant. Transform your residual materials into valuable assets while reducing your waste disposal costs with a briquetting press! It’s an efficient way to maximize your resources and minimize waste.

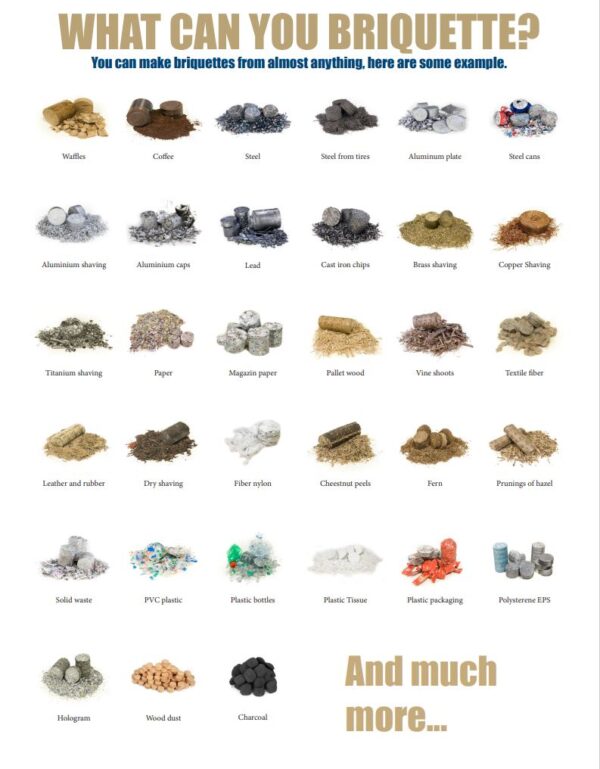

Able to briquette iron, aluminum, steel, stainless steel, cast iron, copper, brass, bronze and even some types of plastic. The machine works automatically, can be timed and can be interfaced with lathes or machine centers.

The BTT Line Briquette Machines feature all-inclusive technology, including advanced control and automation systems to maximize efficiency. These machines are designed to be intuitive and user-friendly, reducing staff training time and enhancing productivity.

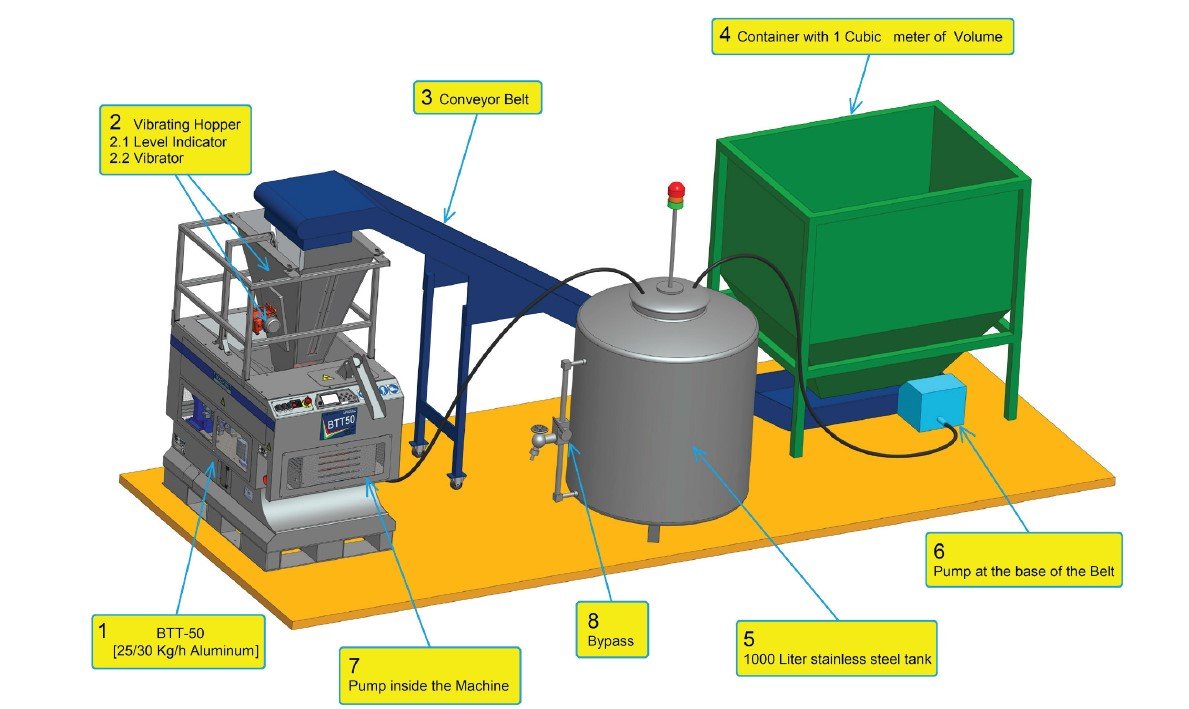

The Mackma BTT50 Briquette Machine is the most compact in its class, offering advanced technology within a footprint of just 80×120 cm. Its height is adjustable, ranging from a standard 110 cm down to 60 cm or up, depending on the customer’s needs.

This machine compresses shavings, reducing their volume by up to 90% with a pressure of 1000 Kg per cm² and extracts 98% of the liquid present in the shavings. It features a 50-liter liquid collection tank, a float, and an automatic pump that directs the liquid to the central processing unit.

It has various accessories such as an external shredder to reduce the size of long chips or skeins; an external hopper with vibrator for shavings that tend to compact; an integrated drainage system for chips with a high percentage of oil; an ultrasonic level sensor to check the filling status of the hopper.

The main advantages of using Mackma briquetting machine are:

- Volume reduction -70%

- Constructed with high-quality materials – long-lasting durability and reliability.

- Reduction of handling and transport costs -80%

- Reduction of recycling costs

- Reduction of environmental impact

- Reduction of environmental pollution

- Increase in value and melt yield + 90%

- Oil recovery

- Compact footprint allows for placement at the work center

Technical specifications

- Briquette diameter 65 – mm

- Production rate (Kg/hour) Aluminum 60÷70

- Production rate (Kg/hour) Iron 120÷140

- Machine used for the compression of metallic chip removed through metalworking operations

- Several benefits, such as: – Machining operation with automatic cycle (no manpower for chip handling) – Recovery of plant areas – Re-use of recovered oil by briquette machine

- Easy to use

- Reduced dimensions

- Suitable for all plant layouts

- Chip material to be compressed: all materials with mechanical machining residues (iron, aluminum, brass, saw, others)

- Application fields: All sectors with mechanical machining

BTT50 – Ø BRIQUETTE 55 mm – Pressure at 1000 kg per cm², 3 to 5 briquettes per minute – Bestseller

- 25-30 Kg/h

- 60-70 Kg/h Iron

- 130/150 Kg/h Copper

- 100-130 Kg/h Cast Iron

- 60-70 Kg/h Steel

- 120-140 Kg/h Brass

BTT60 – Ø BRIQUETTE 60 mm – Pressure at 1000 kg per cm², 3 to 5 briquettes per minute

- 30-60 Kg/h Aluminum

- 70-120 Kg/h Iron

- 140-160 Kg/h Copper

- 130-160 Kg/h Cast Iron

- 70-120 Kg/h Steel

- 140-190 Kg/h Brass

BTT65 – Ø BRIQUETTE 60 mm – Pressure at 1000 kg per cm², 3 to 5 briquettes per minute

- 60-70 Kg/h Aluminum

- 120-140 Kg/h Iron

- 160-180 Kg/h Copper

- 160-190 Kg/h Cast Iron

- 120-140 Kg/h Steel

- 190-230 Kg/h Brass

BTT75 – Ø BRIQUETTE 75 mm – Pressure at 1000 kg per cm², 3 to 5 briquettes per minute – Bestseller

- 90-100 Kg/h Aluminum

- 180-200 Kg/h Iron

- 230-260 Kg/h Copper

- 280-300 Kg/h Cast Iron

- 180-200 Kg/h Steel

- 290-350 Kg/h Brass

BTT85 – Ø BRIQUETTE 85 mm – Pressure at 1000 kg per cm², 3 to 5 briquettes per minute

- 180-200 Kg/h Aluminum

- 360-400 Kg/h Iron

- 330-360 Kg/h Copper

- 400-430 Kg/h Cast Iron

- 360-400 Kg/h Steel

- 420-450 Kg/h Brass

BTT95 – Ø BRIQUETTE 95 mm – Pressure at 1000 kg per cm², 3 to 5 briquettes per minute

- 360-400 Kg/h Aluminum

- 720-800 Kg/h Iron

- 490-520 Kg/h Copper

- 580-610 Kg/h Cast Iron

- 720-800 Kg/h Steel

- 690-720 Kg/h Brass

BTT105 – Ø BRIQUETTE 105 mm – Pressure at 1000 kg per cm², 3 to 5 briquettes per minute

- 720-800 Kg/h Aluminum

- 1400-1600 Kg/h Iron

- 920-940 Kg/h Copper

- 980-1100 Kg/h Cast Iron

- 1400-1600 Kg/h Steel

- 1100-1300 Kg/h Brass