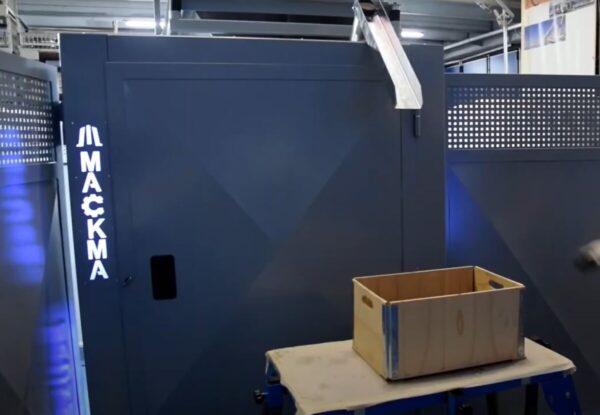

MACKMA – BTF-C Line – Briquetting Machines for Grinding Sludge

Description

BTF-C50 – Ø Briquette 35 mm – Pressure: 2500 Kg/cm², 3 to 5 Briquettes per Minute

- 15-20 Kg/h Grinding Sludge

- 15-30 Kg/h Iron

- 20-50 Kg/h Cast Iron

- 15-30 Kg/h Steel

BTF-C65 – Ø Briquette 45 mm – Pressure: 2500 Kg/cm², 3 to 5 Briquettes per Minute

- 20-30 Kg/h Grinding Sludge

- 30-70 Kg/h Iron

- 50-90 Kg/h Cast Iron

- 30-70 Kg/h Steel

BTF-C75 – Ø Briquette 55 mm – Pressure: 2500 Kg/cm², 3 to 5 Briquettes per Minute

- 30-70 Kg/h Grinding Sludge

- 60-90 Kg/h Iron

- 90-130 Kg/h Cast Iron

- 60-90 Kg/h Steel

BTF-C85 – Ø Briquette 65 mm – Pressure: 2500 Kg/cm², 3 to 5 Briquettes per Minute

- 70-120 Kg/h Grinding Sludge

- 90-140 Kg/h Iron

- 130-190 Kg/h Cast Iron

- 90-140 Kg/h Steel

BTF-C95 – Ø Briquette 75 mm – Pressure: 2500 Kg/cm², 3 to 5 Briquettes per Minute

- 120-180 Kg/h Grinding Sludge

- 140-200 Kg/h Iron

- 200-300 Kg/h Cast Iron

- 140-200 Kg/h Steel

BTF-C105 – Ø Briquette 85 mm – Pressure: 2500 Kg/cm², 3 to 5 Briquettes per Minute

- 180-230 Kg/h Grinding Sludge

- 200-400Kg/h Iron

- 300-430 Kg/h Cast Iron

- 200-400 Kg/h Steel