MACKAM – Automatic Briquetting Line: Comprehensive Solution for Chip Management

Description

Optimise Your Production with the Mackma Automatic Briquetting Line

The Mackma automatic briquetting line represents the forefront of metal chip management and transformation. Comprised of a conveyor belt, a chip collection tank, a liquid collection tank, and a shredder for long chips, this line ensures efficient, uninterrupted operation. Discover how our comprehensive solution can improve your production and reduce disposal costs.

Key Components of the Automatic Briquetting Line

Conveyor Belt

- The Mackma conveyor belt is designed for the continuous and reliable transport of metal chips from the machine tool to the collection tank. Built with durable materials, it ensures long-lasting, trouble-free operation.

Chip Collection Tank

- The chip collection tank is an essential component for chip accumulation before briquetting. Designed to handle large volumes, this tub facilitates the briquetting process and optimizes your workspace.

Liquid Collection Tank

- The liquid collection tank gathers the oils and coolants present in the chips, allowing for their reuse or proper disposal. This system reduces waste and enhances your company’s ecological efficiency.

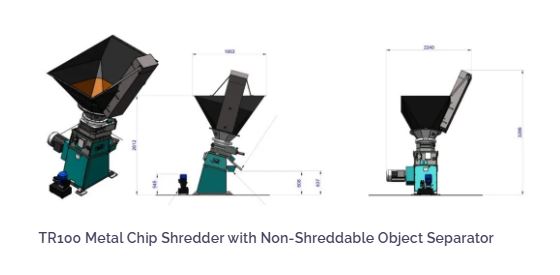

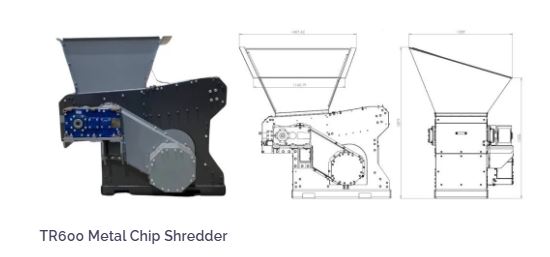

Shredder for Long Chips

- The shredder for long chips is crucial for preparing chips for briquetting. Capable of handling long and bulky metal chips, the shredder reduces chip size, making the compaction process easier.

Automatic Briquetting Line with Shredder: Efficiency and Safety

Innovating Chip Management with the Mackma Automatic Briquetting Line

Optimise your metal chip management with our automatic briquetting line, equipped with an advanced shredder. This comprehensive solution not only simplifies the chip transformation process but also ensures safety and durability thanks to the shredder’s drawer for non-shred able pieces.

Advanced Shredder with Automatic Ejection Drawer

- The shredder integrated into our automatic line is designed to handle even the longest and most cumbersome metal chips. A distinctive feature of our shredder is the automatic ejection drawer, which opens to remove non-shred able pieces. This innovative system prevents damage to the shredder blades and the briquetting machine’s pressing chamber, ensuring uninterrupted operation

Advantages of the Automatic Drawer

- Safety: The automatic drawer protects the shredder blades and the briquetting machine components, avoiding costly repairs.

- Efficiency: The automatic removal of non-shred able pieces allows the system to operate continuously, without interruptions and without the need for a nearby operator.

- Reduced Maintenance: With fewer risks of damage, downtime for maintenance is significantly reduced, increasing productivity.

Benefits of the Mackma Automatic Briquetting Line

- Volume Reduction of Chips: Our automatic line reduces chip volume by up to 90%, optimising storage space and lowering disposal costs.

- Liquid Recovery: The advanced liquid collection system allows the recovery of up to 98% of oils and coolants, contributing to ecological sustainability and reducing waste.

- Increased Productivity: With a shredder equipped with an automatic drawer for non-shred able pieces, the Mackma automatic line ensures continuous, uninterrupted operation, significantly improving productivity.

- Customised Solutions: Each automatic briquetting line can be customised to meet the specific needs of your production. We offer tailored solutions to perfectly integrate with your production processes.