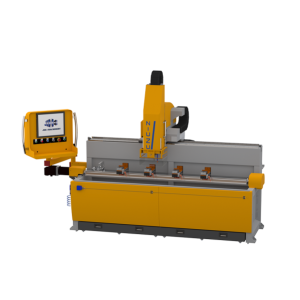

JIH-CNC S5 Type 5 Axis CNC Machining Centre

Specifications

| Make | JIH |

|---|---|

| Model | CNC S5 |

Description

JIH-CNC S5 Type 5 Axis CNC Machining Centre

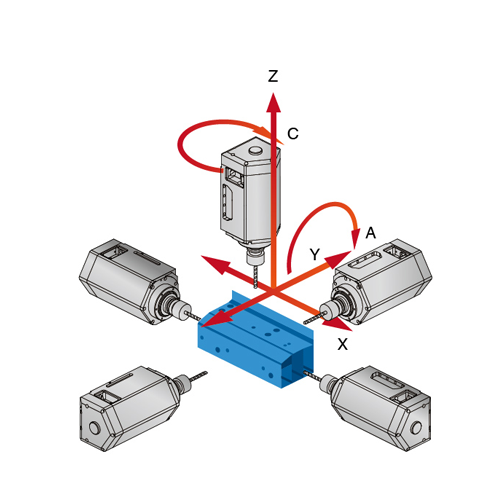

5-Axes Machining Centre

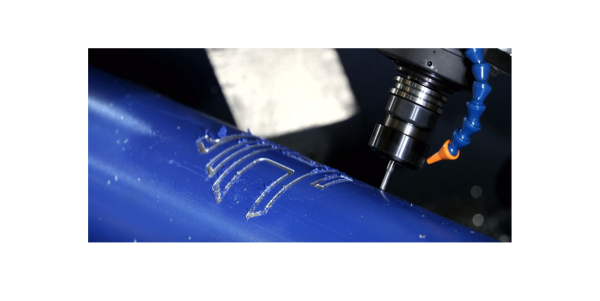

- Any surface or plane in 3D space can be processed.

- 5 axis can rotate into any angle and direction.

- Even machining irregular profile, 5 axis can keep specific angle to the surface.

- Specifically for aluminum material, POM, light alloy cutting, drilling, slotting, machining.

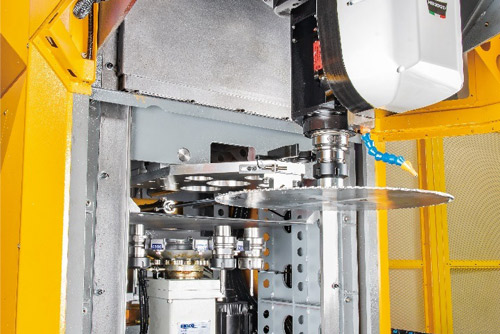

- Syntec 5 axis controller, with 5 axis head which imported from Italy, can make the five-sided machining once.

- Tempering treatment heavy base keeps strong and accuracy.

- German CAM software and vise automatic positioning function, make the 5 axis machining process more simplify.

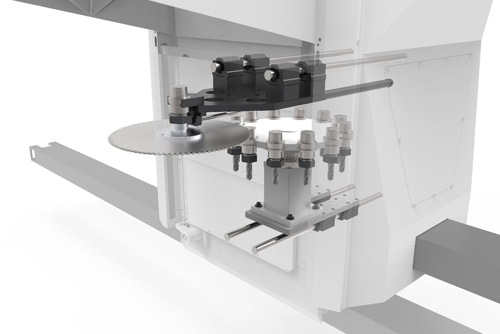

- The angular head can be tilting A-Axis : ±120˚, Spindle rotary C-Axis : ±120˚, Spindle rotary C-Axis : ±220˚, making it suitable for angular drilling and tapping operations. Suitable for face milling and multi-surface machining in one setup.

- Tilting degree through computer control.

- Angle Indexing accuracy

- A tool clamp / release button is provided on the angular head.

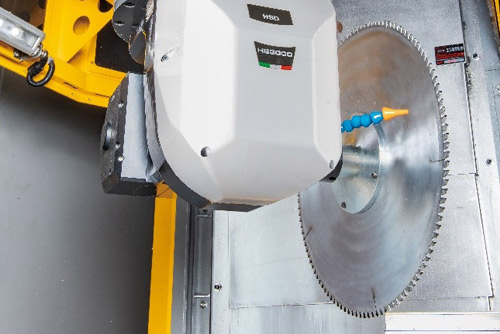

- Integrated type spindle features high accuracy, low vibration, low noise and no backlash

Machine Features

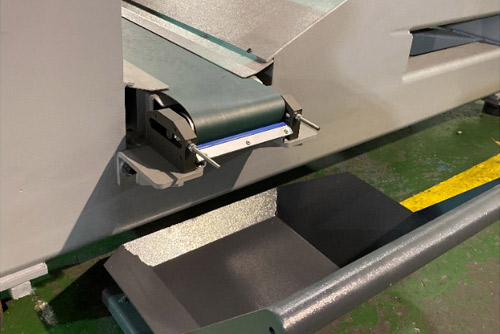

- Equipped with two-layer tool magazines for storing sawblade and cutting tools on both upper and lower magazine, featuring fast tool change.

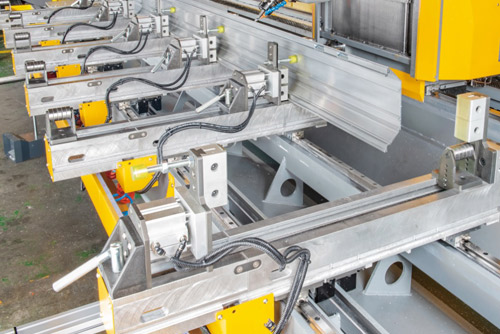

- Specially designed clamping for irregular workpieces to keep the clamping stable. The clamp is equipped with roller to avoid workpiece damage.

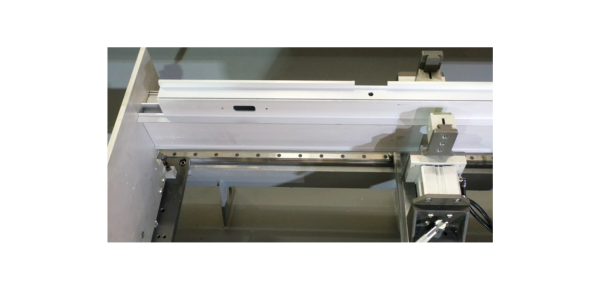

- Automatic clamp moving and positioning system combined with automatic clamp position sensing function effectively prevents the crash from spindle hitting the vise.

Applicable Materials

- Aluminum

- Other non-ferrous metals

Applicable Industries

- Public transportation, aluminum, light alloy profile processing.

- Aerospace industry.

- long-shaped aluminum profiles.

- Square tube profile cutting, drilling, slot milling.

- Aluminum doors and Windows industry

- Curtain wall(glass wall)

- Extruded aluminum

- Long material parts

| MODEL | JIH-CNC S5 (5 Axis) |

|---|---|

| Stroke | |

| X Axis Stroke | 3,500 mm/4,500 mm/5,500 mm/6,500 mm(Opt.) |

| Y Axis Stroke | 400 mm (5 axes) (3 axes: 700 mm) |

| Z Axis Stroke | 800 mm (saw blade processing stroke 350 mm) |

| A Axis Swivelling Angle | ±120° |

| C Axis Swivelling Angle | ±220° |

| Table | |

| Table Type | vise |

| Table Size | 400 X 3,500 ~6,500mm |

| Table Height From Floor | 680 mm |

| Spindle | |

| Spindle Speed | 20,000 R.P.M. |

| Spindle Motor | 10HP (7.5kw) |

| Spindle Taper Cone | HSK 63F |

| Sawblade size | 16″X1″ bore |

| Feed Rate | |

| Rapid Feed Rate (X / Y / Z) | X:50 m/min,(Opt. 70 m/min) Y:24 m/min, Z:24 m/min A:75°/S, C:75°/S |

| Servo Motors of 3 Axis | X:2.9 kw , Y: 850w, Z: 1.8 kw, A:750w, C:750w |

| Cutting Feed Rate | F:1 ~ 5,000 mm/min |

| Repeatability Accuracy | X: ±0.02 mm Y: ±0.01 mm Z: ±0.01 mm |

| ATC | |

| Magazine Capacity | 12 Tools |

| Tool Holder | HSK63F |

| Dimensions | |

| Required Pneumatic Pressure | 6 kgs/cm2 |

| Machine Dimensions(LxWxH) | 8,000 ~ 11,000 x 3,150 x 3,900 mm |

| Packing Dimensions(LxWxH) | 8,100 ~ 11,100 x 2,300 x 2,450 mm |

| Machine Weight | 4,500 ~ 6,500 kgs |