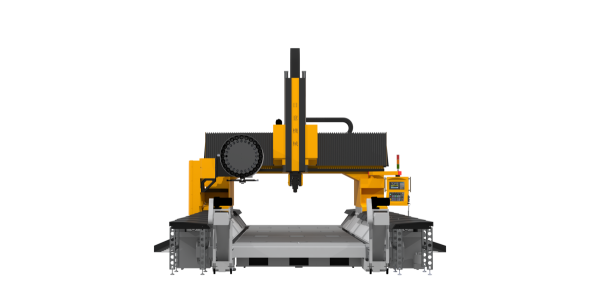

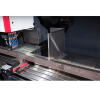

JIH-CNC 650G Type Gantry Type Double Column Machining Centre

Specifications

| Make | JIH |

|---|---|

| Model | CNC 650G |

Description

JIH-CNC 650G Type Gantry Type Double Column Machining Centre

Machine Features

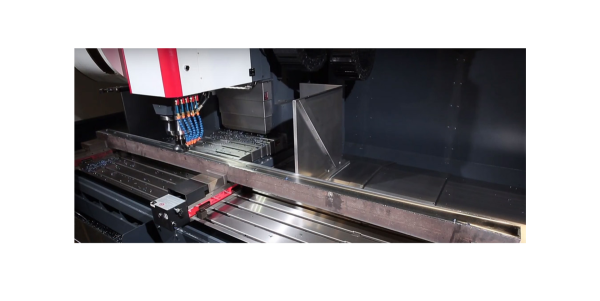

- Fixed table in combination with traveling column and beam that makes the machine suitable for machining extra large workpieces.

- X-axis travel is transmitted through pinion/rack and driven by a gearbox, featuring high torque output, no backlash and high positioning accuracy (optional).

- X-axis rapid traverse rate is 36 M/min. Upon request, high rapid traverse rate up to 50 M/min is available (optional).

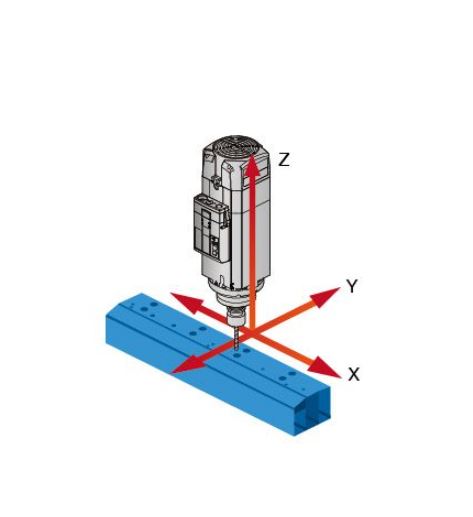

- Three axes are equipped with P class high precision linear guide ways. X,Y,Z-axis ball screws are directly coupled with servo motors.

- 24-tools magazine.

- Syntec controllers-PC-based, (Opt. Mitsubishi, Fanuc and Siemens).

- To avoid the tool interference, the design is conducive to machining complex part

- To the multiple-face machining in the once , good for the face position accuracy

- When the 5 axis machining, tool can fit the irregular face

- 4 linear guides for Z axis, with high rigidity head

- Z axis with pneumatic balance system, improve Z axis reactivity

Applicable Materials

- Aluminum

- Steel, tools

- Metal (such as: linear way and round bar, etc.)

- Other non-ferrous metals

- Styrofoam, Bakelite, Wood, Non-metal, Carbonized hybrid material

Applicable Industries

- Aluminum door and windows

- Curtains wall (glass wall)

- Extruded aluminum

- Long material parts

- Mould Carving

- Mould industry: casting, automobile, wind energy, shipbuilding, aerospace and rail transportation

Product Specification

| Model | JIH-CNC 650G |

|---|---|

| Stroke | |

| X Axis Stroke | 6,500 mm(Opt)~10,000mm |

| Y Axis Stroke | 2,500 mm |

| Z Axis Stroke | 1,200 mm |

| Distance from spindle nose to table surface | Min150 mm, Max1,350 mm |

| Table | |

| Table Type | T-slots (opt. T-slots Table) |

| Table Size | 6,500 x 2,500 mm |

| Max. Loading Capactity | 20 ton |

| T-Slot(NO. x Pitch x Size) | 15 x18 x400 mm |

| Spindle | |

| Spindle Speed | 6,000 R.P.M. |

| Spindle Motor | 15 kw (18kw opt.) |

| Spindle Taper Cone | BT 50 |

| Feed Rate | |

| Rapid feed rate (X/Y/Z) | X:16 m/min, Y:20 m/min, Z:20 m/min |

| Servo Motors of 3 Axis | X1=X2: 4 kw; Y: 4kw; Z: 7kw |

| Cutting Feed Rate | F: 1~5,000 mm/min |

| Repeatability Accuracy | X:±0.03 mm, Y:±0.02 mm, Z:±0.02 mm |

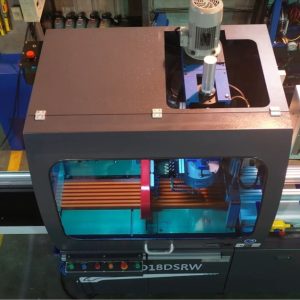

| ATC | |

| Magazine Capacity | 24 Tools |

| ATC Type | Arm Type |

| Tool Holder | BT 50 |

| Pull Stud | 45° |

| Max. Tool Length | 350 mm |

| Max. Tool Diameter | 120 mm |

| Max. Tool Weight | 16 kgs |

| Dimensions | |

| Machine Weight | 50 ton |

| Machine Dimensions | 11,200 × 6,700 x 5,400 mm |

| Required Pneumatic Pressure | 6 kgs/cm² |