IMET – XSMART3 – Automatic Double Column Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | XSMART3 |

Description

IMET – XSMART3 – Automatic Double Column Bandsaw

Automatic bandsaws for every working environment

XSMART3 is an automatic double column bandsaws for straight cuts and totally managed by CNC with 7″ touch screen display, easy and intuitive interface. Fully protectedy by carters to provide maximum security to the user, it’s an easy to use professional tools that can be installed in every environment and mechanic workshop.

TECHNICAL INFORMATION

| Cutting capacity at 0° | Round 310 mm. Square: 310mm Rectangular: 340x310mm |

| Cutting capacity at 0° with solids (C45) | 250 mm |

| Cutting capacity with bundle cutting | Max. 340×250 mm Min. 130×10 mm Scrap-end: 280mm |

| Minimum cutting length | 15 mm |

| Blade size | 3730x34x1.1mm |

| Canted blade | 0° |

| Blade motor | 3 KW |

| Feeder length | 500 mm |

| Feeder motor power | 0.75 KW |

| Minimum scrap-end | 90 mm |

| Blade speed | 15/100 m/min |

| Hydraulic unit motor power | 0.75 KW |

| Hydraulic unit tank capacity | 20 l |

| Coolant tank capacity | 50 l |

| Size – Weight – Working area height | 1950x1755x1965mm 1650kg 920mm |

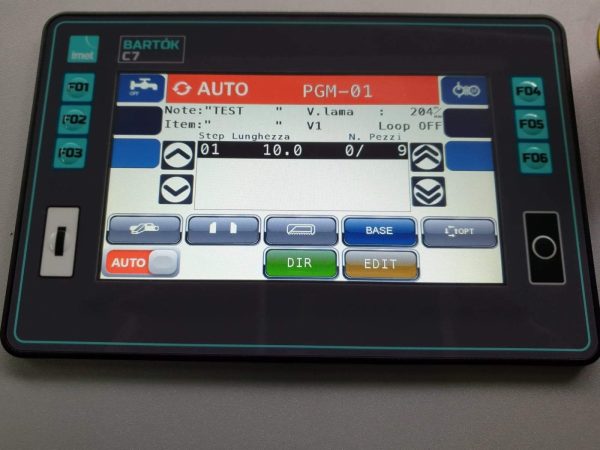

7″ touch screen display: XSMART3 has an easy, intuitve and user-friendly interface with a 7″ touch screen display that allows to have full control on all the machine parameters and all the operative settings. Using CNC system, the user will have the possibility to optimize his user-experience and workflow with just few clicks. These features, combined with the solid structure, make XSMART3 the perfect working tool for industry applications.

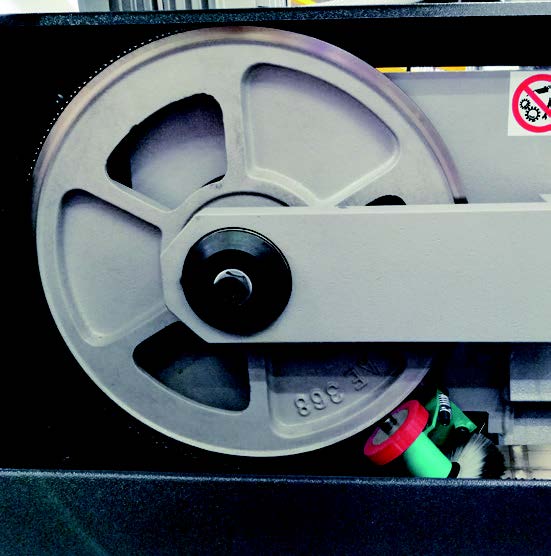

Sawframe: XSMART3 sawframe has an elctrowelded rigid structure on double column which helps reduce vibrations and binding during descent. Like many IMET bandsaws, its blade is canted (30°) to reduce the band strain and have better and constant sawframe descent while cutting with optimized performances on every material, profiles or solid.

Feeder with roller table: XSMART feeder has a single stroke of 500mm with integrated roller table for material support. The feeder moves with a recirculating screw and electric motor with inverter, portal structure that ease material movement and loading.

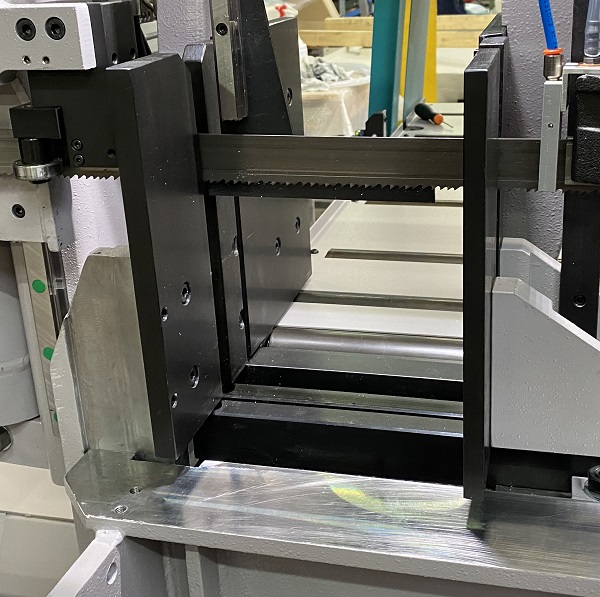

Full stroke vice: The machines uses an hydraulic full stroke vice to lock the material wtih jaws place both before and after the cutting line.

Blade cleaning: All the semiautomatic and automatic IMET bandsaws are equipped with a mechanical cleaning brush with nyloni fibers that helps to remove residuals and remainings while cutting.

Washing gun: Premium Line automatic bandsaws and semiautomatic and automatic Maxi Line bandsaws are standardly equipped with a washing gun dedicated to keep clean the working area and remove any residuals and remainings, allowing to keep the highest efficiency of the machine.

Blade guide: Hard metal blade guides with bearings to have optimal blade alignment during the cutting process. The mobile blade guide is kept automatically next the cutting point.

Chips conveyor: Standard on XSMART3 there’s a chip conveyor that helps remove any material remaining while the machine works.

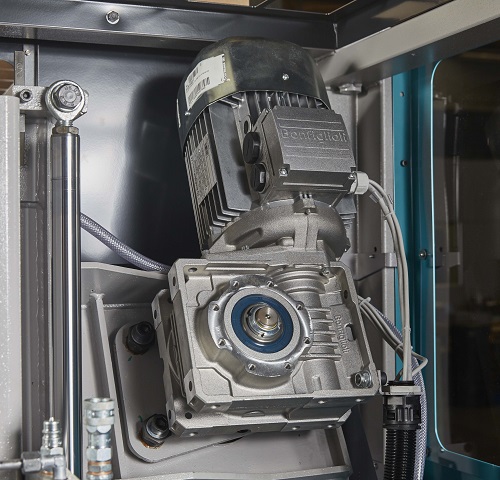

Bonfiglioli motor-reducer: XSMART3 uses Bonfiglioli motor-reducer to have the highest reliability and functionality.