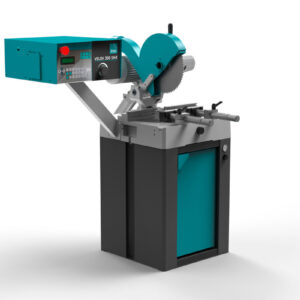

IMET – XS 1250 – Industrial Semiautomatic Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | XS 1250 |

Description

IMET – XS 1250 – Industrial Semiautomatic Bandsaw

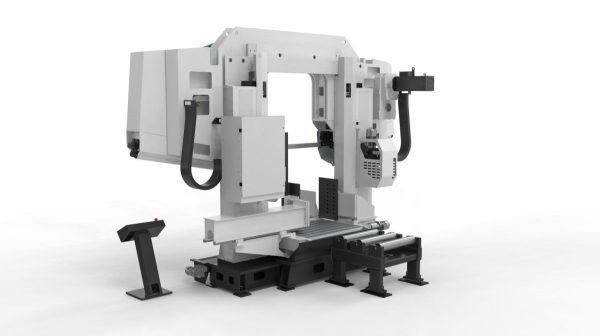

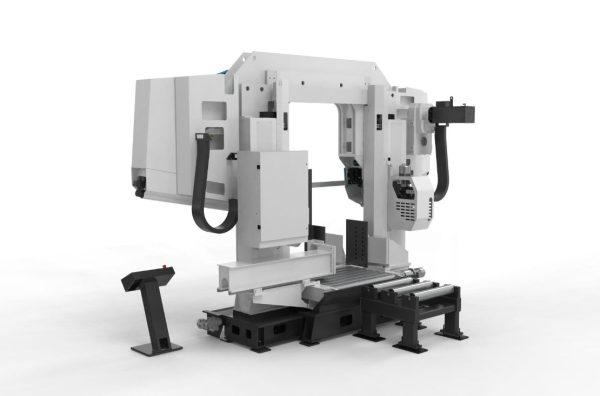

XS 1250 is the big size, industrial application semiautomatic bandsaw suitable to cut big dimension profiles and solids of special steels with vertical descent and straight cut. The machine is the perfect industrial tool, able to support o big format pieces thanks to wide working area and 7 motorized integrated rollers.

Steel and big size structure sawframe: Build in strong electro-welded steel with double sections and big thickness, the XS 1250 has big structure to avoid vibrations and noise while working; the sawframe movement is provided by the recirculating ballscrws with two brushless electric motors. These features allows to have high cutting performances while saving blade life. The pulleys have a 1300 mm diameter with tubular electro-welded structure, hardened at 55 HRC.

Wide working area with motorized rollers: The machine is intended to cut big size solid materials to it has a wide working area able to support big volume pieces thanks to the 10 electric motorized rolls managed by the inverter; 7 rolls support the material before the blade, while 3 are placed after the band. All the rollers can be moved together or independently (before and after the cut) to ease the piece detachment process so that the blade could ascent without scratching the cut piece: this system is crucial when cutting hard or special steels.

Vice: Hydraulic material locking vice that slides horizontally on the working table upon recirculating ballscrews so that the material clamping system is precise with perfect positioning of the piece. Jaws height: 700mm. mm.

Blade alignment: XS 1250 blade guides has hard metal pads and include cemented, hardened, rectified lateral rolls with easy regulation. The blade guide is kept next automatically close to the cutting area.

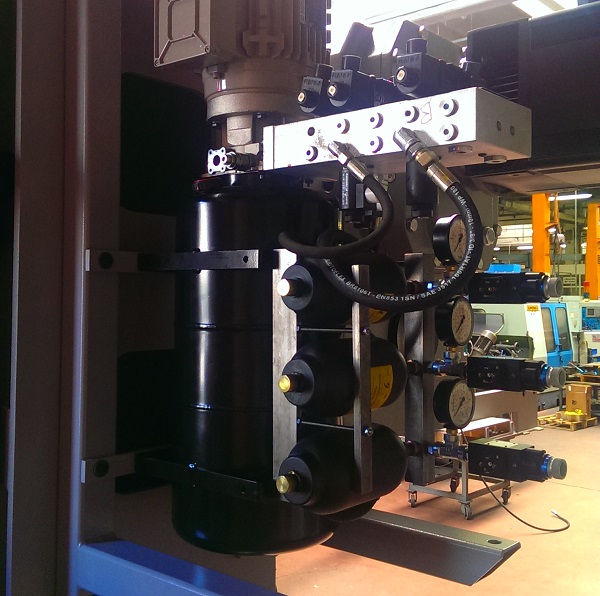

Hydraulic unit: Hydraulic unit provides for low noise level and constant working pressure. The unit turns on only for vices, hydraulic blade guides and blade tension device movements; when the pressure level dramatically lowers (detected by pressure switches), the unit will turn on automatically while the cutting process is subdue with the unit turned off (the unit has vice pressure reducer supplied as standard). Machine manuals for hardware, software and maintenance also supplied.

Tensionamento: Blade tensioning system is adjustable based on the material and is provided by a 180mm diameter hydraulic cylinder while the machine software checks the tension to have it perfectly set. If the machine isn’t used for a while, the automatic control will release the band to avoid useless stress and strain on it. If breakage is detected, the cutting process immediately stops.

Chip Conveyor System: The machine has an external chip conveyor with electric movement and a tank to collect residuals and coolant liquid (250l). To have a better cleaning of the cutting parts, the chip conveyor is canted with carter on the pulleys. It can works in 3 ways: always on, only while cutting, always off.

TECHNICAL INFORMATION

| Cutting capapcity at 0° | Round: 1250mm Square: 1250mm Rectangular: 1250x1250mm |

| Blade motor | 18KW |

| Blade speed | 14 80 m/min |

| Blade size | 12450x80mmm |

| Blade tension | 3500kg/cm2 |

| Canted blade | 0° |

| Working table height | 760mm |

| Hydrulic unit motor power | 3KW |

| Hydraulic unit tank capacity | 80 l |

| Coolant tank capacity | 220 l |

| Weight | 13000kg |

| Size | 5960x2890x4000mm |