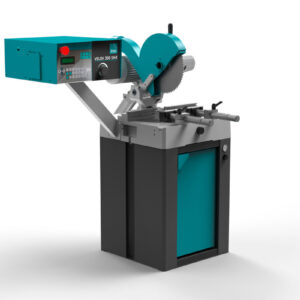

IMET – VELOX 350 AF-NC – CNC Automatic Circular Machine For Aluminium

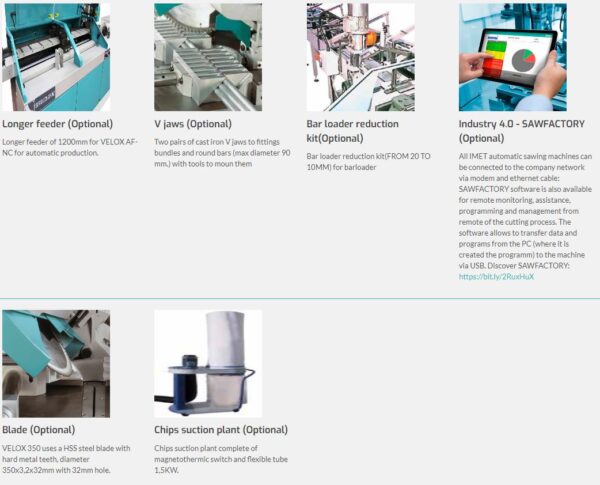

Specifications

| Make | IMET |

|---|---|

| Model | VELOX 350 AF-NC |

Description

CNC Automatic Circular Machine For Aluminium

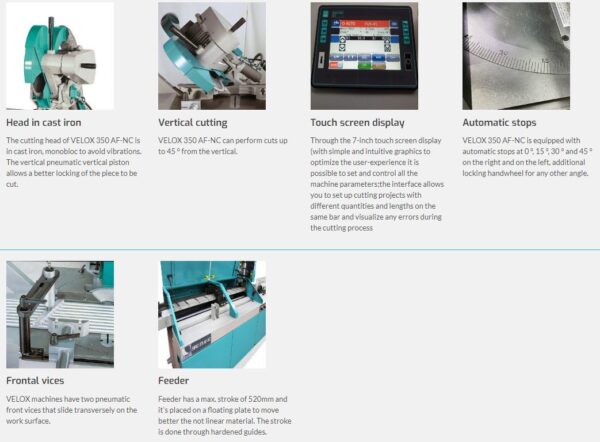

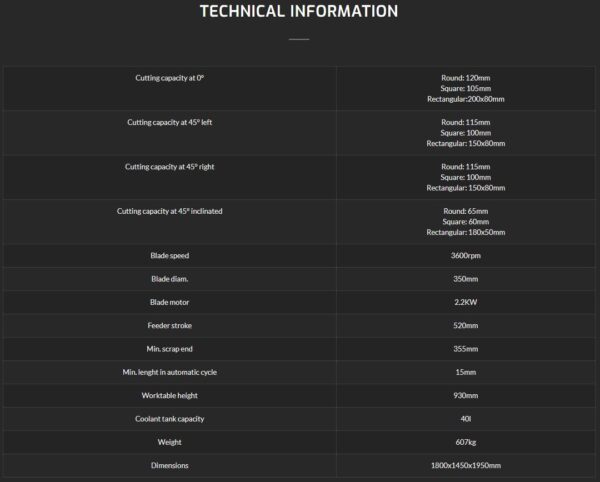

- Automatic CNC circular saw suited to cut aluminum light metal solids and profiles with high accuracy.

- Possibility to set the machine for brass and copper profiles.

- Mitre cutting from 0° to 45° left and right.

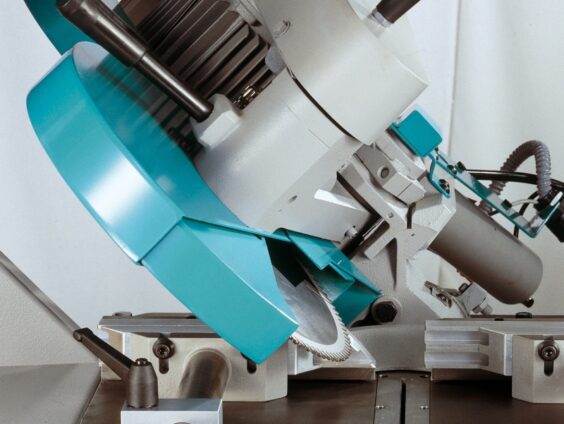

- The head bends 45° on the vertical axis to allow inclined cuts.

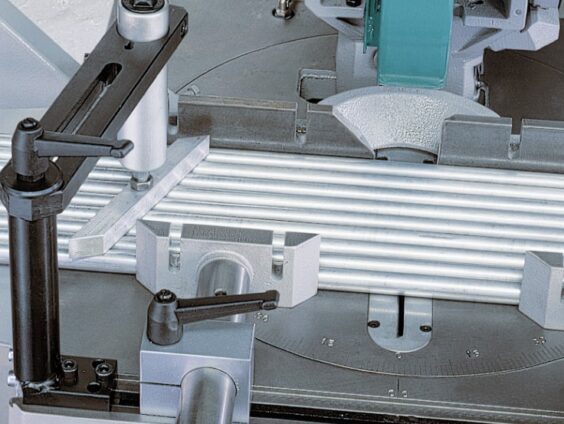

- Easy stops at 0°, 15°, 30°, 45° left and right, hand-wheel to lock the head on all angles.

- Electro-pneumatic functioning, hydraulic control of the down-feed speed of the head.

- Programming of all operations by means of the CNC driver, including the setting of the cutting lengths (min 4 mm) with automatic feeder strokes.

- Start-cut and end-cut points; machine status is shown on display, including blade speed, piece counter, total material length to cut; working anomalies and in different languages by means of the keyboard.

- A feeder with a 200 mm opening, moving by an electronic motor with an inverter.

- Minimum stroke 4 mm (minimum scrap-end 355 mm).

- Up to 99 programs can be memorized, each one with different cutting lengths and a number of cuts.

- Pair of front pneumatic vices with quick clamping, free to move alongside the worktable, vertical pneumatic vice.

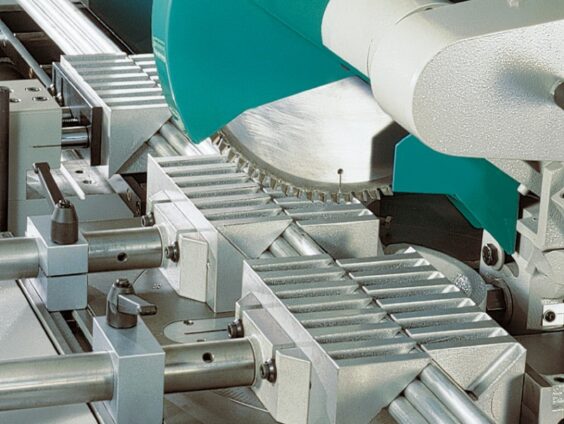

- Upper roller to cut more bars in a row. Complete blade protection, able to connect chip suction plant.

- The complete guard opens only when the blade is still. Fixed protection on the unloading side.

- Floor stand with removable tank and chip collector, connection element to the unloading side.

- Lubrication system with spray working only during the cut. Air filter/reducer/ lubrication group.

- Main switch with minimum tension coil, emergency button, thermic and magnetic motor protection, motor absorption device, 24V low tension.

- Programming of all operations by CNC control board easy to use complete of display that shows machine status and anomalies.

- Cast iron head avoids vibrations. Additional vertical pneumatic vice guarantees perfect material locking.

- Cutting capacity at 90 ° round till 120 mm., square till 105 mm. 200×80 mm.