IMET – KTECH 802 F3000 – Automatic Double Column Bandsaws With CNC Control

Specifications

| Make | IMET |

|---|---|

| Model | KTECH 802 F3000 |

Description

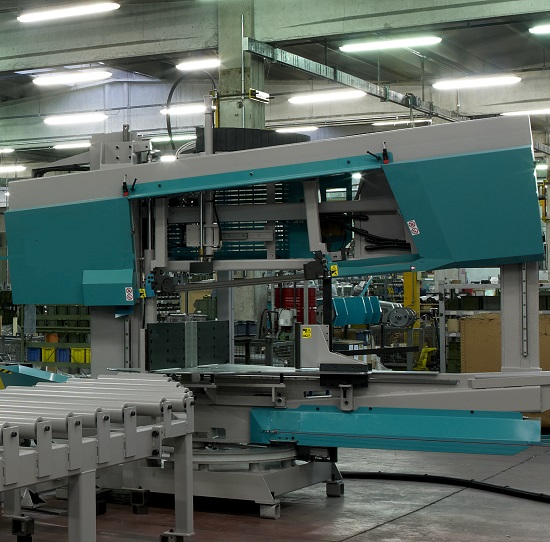

IMET – KTECH 802 F3000 – Automatic Double Column Bandsaws With CNC Control

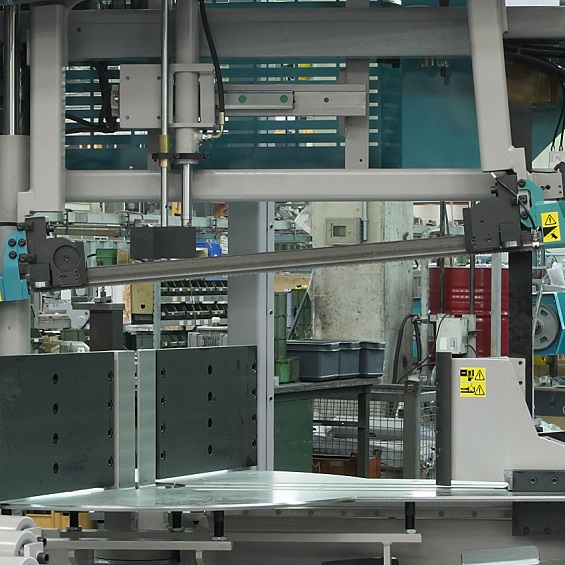

KTECH 802 is an automatic double column bandsaw suitable to cut bars, tubes, solids and profiles up to 60° both on left and right.An automatic sawing machine with CNC managed feeder and sawframe movement, KTECH has 10″ touch screen display to manage the cutting process. The perfect working tool for professionals, big size production and industry application.

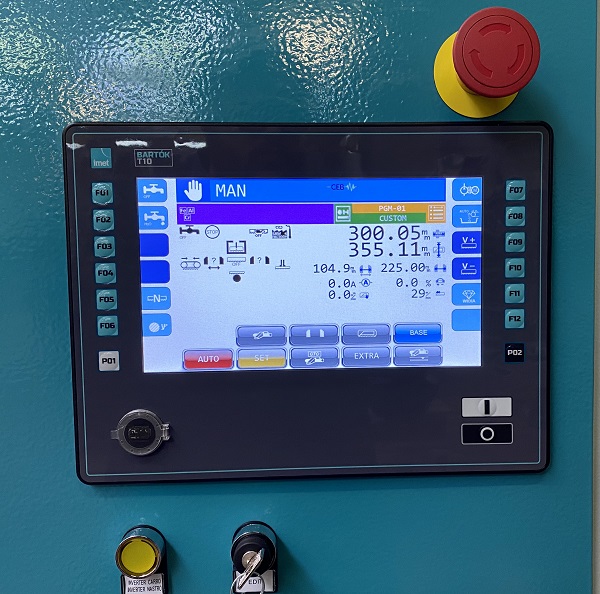

10″ Touch screen display

KTECH 802 has an easy and intuitive interface dedicate to optimise the user-experience: thanks the CNC system and 10″ touch screen display the user can manage all the machine operative function, set up 99 cutting program and multiple cutting length on the same bar, set the number of feeder stroke, the number of pieces and blade speed. It’s also possible to do an auto diagnostic to detect errors.

CNC managed axes system

KTECH line automatic bandsaws have a CNC managed axes system (3 both for 802 and 1202 models: vice closing, material feeding and sawframe rotation) that can be set and controlled by touch screen (and SAWFACTORY).

Sawframw

The electro welded sawframe structure developed by our technicians has big thickness and allows to avoid vibrations and noise while working. Band pulleys are supported through big size bearings with metal plate to have the better alignment. Sawframe movement perfectly balanced by big diameter hydraulic cylinder and linear guides.

Precision and accuracy

IMET automatic and semiautomatic bandsaws uses an innovative angle measurement system located outside the machine centre so that the angle precision and accuracy is always as high as possible, even on left and right angular cuts.

Motorized sawframe rotation

IMET’s KTECH and KS NC bandsaws has a CNC managed and motorized sawframe rotation system (where all the parameters can be set by touch screen display. Sawframe rotation is made possible by an hydraulic cylinder.

Canted blade

To increase material penetration, avoid lowering slowdown and save blade life, KTECH machines have a 5° canted blade that helps to optimize the cutting process even on bigger and stronger profiles.

Blade tension

Blade tension is managed by a mechanic/hydraulic system. Ideal blade tension (which is 2000kg/cm2) can be set via touch screen display and machine software. If a breakage happens, Ktech software immediately stops the process, allowing maintenance.

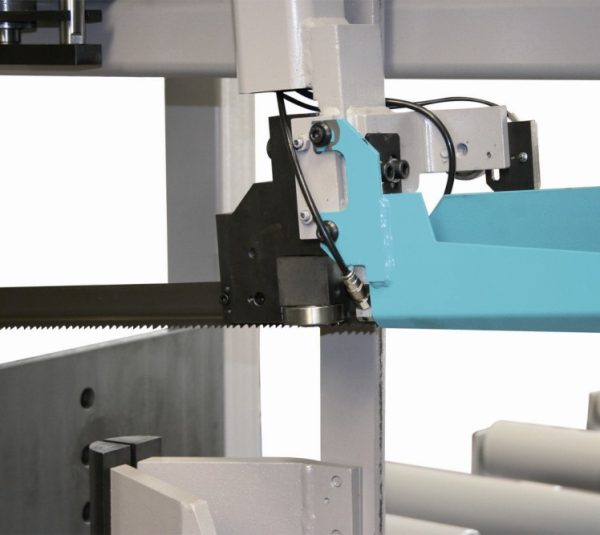

Blade guides

Hard metal blade guides with lateral guide cemented rolls, hardened and rectified with easy regulation system. Mobile blade guides is automatically kept next to the cutting area for a better blade alignment and highest precision.

Blade cleaning

An adjustable and mechanic motorised metal cleaning brush provides to remove residuals and remaining on the blade while cutting. Minimal lubrification is a standard equipped to avoid liquid dispersion that could affect the length measurement.

Vice

Horizontal vice with round jaws so that the material can be locked on every set angle. This design allows to lock the material as close as possible to the cutting line on both bar sides, easing the process on every angle. Jaws height is 370mm.

Integrated feeder

KTECH has an integrated feeder with an integrated roller table, length 3000mm. Feeder movement and repetition are set via touch screen display. Cutting material is fully supported by the roller table, while final scrap-end is 150mm.

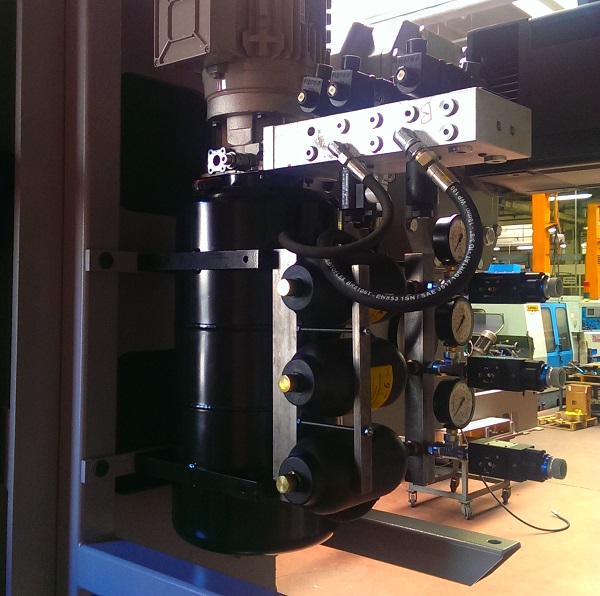

Hydraulic unit and saving energy.

Hydraulic unit of new design with new low noise pump and locking valves on all the movements, with vice pressure reducers. Most processes are carried out with switched off hydraulic unit that allows a considerable saving of energy and maintains low oil temperature.

Standard minimal lubrification

Standard minimal lubrification keeps the material dry, avoiding waste. The system can work in 3 ways: always switched on, switched-on only while cutting, switched-off. If the oli isn’t enough, it’s reported on the machine display.

Technical Information

| Cutting capacity at 90° | Round: 680mm Square: 640mm Rectangular: 820x610mm |

| Cutting capacity ata 45° (light) | Round: 550mm Square: 550mm Rectangular: 550x580mm |

| Cutting capacity ata 45° (right) | Round: 550mm Square: 550mm Rectangular: 550x580mm |

| Cutting capacity ata 60° (left) | Round: 370mm Square: 370mm Rectangular: 370x450mm |

| Cutting capacity ata 60° (right) | Round: 370mm Square: 370mm Rectangular: 370x450mm |

| Cutting capacity with bundle device | Max: 800x320mm Min: 80x80mm Scrap-end: 400mm |

| Cutting capacity at 90° (solid C45) | 350mm |

| Blade tension | 2000kg/cm2 |

| Blade size | 7260x41x1.3mm |

| Blade speed | 18 100 m/min |

| Blade motor | 5.5KW |

| Feeder length | 3000mm with automatic repetition |

| Minimum scrap end | 400mm |

| Cutting length | 6 9.999mm |

| Size – Weight | 5850x3700x2700mm (h 815mm) 4800kg |

![IMET – KTECH 352 – F1200 – Automatic bandsaw for structural steels [Made In Italy] IMET - KTECH 352 - F1200 - Automatic bandsaw for structural steels [Made In Italy]](https://www.delahenty.com.au/newwp/wp-content/uploads/2024/10/IMET-KTECH-352-F1200-MAXI-LINE-image01-300x300.jpg)