IMET – KS 802 NC – Semiautomatic Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | KS 802 NC |

Description

IMET – KS 802 NC Semiautomatic Bandsaw

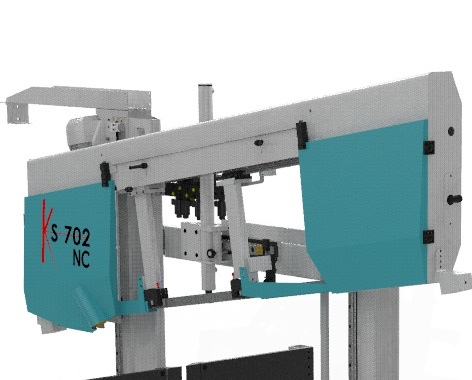

Semiautomatic bandsaw with automatic bow rotation

KS 802 NC is a semiautomatic double column bandsaw suitable to cut pipes, tubes, bars and solid up to 60° on left and right. The machine has the automatic rotation of the sawfram managed by CNC, making it the ideal working tool for batch production and professional applications.

Technical Information

| Cutting capacity at 0° | Round: 680mm Square: 640mm Rectangular: 820x610mm |

| Cutting capacity at 45° left | Round: 550mm Square: 550mm Rectangular: 550x600mm |

| Cutting capacity at 45° right | Round: 550mm Square: 550mm Rectangular: 550x580mm |

| Cutting capacity at 60° left | Round: 370mm Square: 370mm Rectangular: 370x600mm |

| Cutting capacity at 60° right | Round: 370mm Square: 370mm Rectangular: 370x450mm |

| Cutting capacity with bundle device | Max: 800x320mm Min: 50x50mm |

| Cutting capacity at 0° solids (C45) | 350mm |

| Blade size | 7260x41x1.3mm |

| Canted blade | 5° |

| Blade motor | 5.5KW |

| Blade speed | 15/100m/min |

| Coolant tank capacity | 3l |

| Hydraulic unit tank capacity | 25l |

| Working table height | 800mm |

| Size – Weight | 2050x3600x2700mm 3200kg |

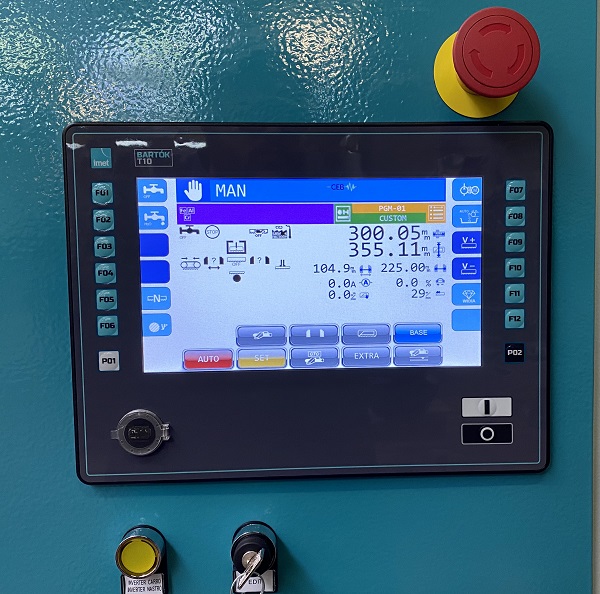

10″ Touch screen display: KS 802 NC has an easy and intuitive interface dedicate to optimize the user-experience: thanks the CNC system, 10″ touch screen display the user can manage all the machine operative function, set up 99 cutting program and multiple cutting length on the same bar, set the number of feeder stroke, the number of pieces and blade speed. It’s also possibile to do an autodiagnostic to detect errors.

Rigid sawaframe: KS 802 NC has big size, electrowelded bow with rigid structure and big thickness. The massive structure helps reduce any vibration, binding or slowing during the cutting process, saving sawblade life and durability. High cutting performances even on the biggest sections and full materials are provided by the 5° canted blade with 2000kg/cm2lade tension.

Sawframe rotation: The machine has an automatic sawframe rotation system managed by toothed belt and motor reducer. Positioning precision is provided by an hydraulic cylinder to stop the rotation. Rotation managed by CNC and 10″ touch screen display.

Lowering speed display: KS 802 NC lowering sawframe speed can be set, managed and view thanks to the LCD display on the panel control.

Canted blade: The 5° canted blade provides for an optimal band penetration in the material white cutting and helps reducing vibration, binding and slowdown during the process, increasing the cutting perfomances, saving the blade life, even when cutting solids material or big section. It’s present a switch that keeps an high blade tension to reduce the string while working.

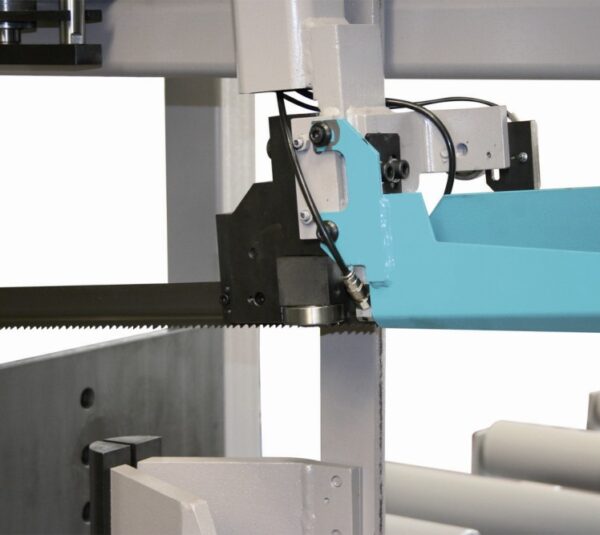

Blade guides: The machine has a mobile blade guide, automatically kept in contact to the cutting point with a gas piston

Blade cleaning: All the semiautomatic and automatic IMET bandsaws are equipped with a mechanical cleaning brush with nylon fibers that helps to remove residuals and remainings while cutting.

User safety: Provided as standard on all the KS NC models, it’s present a user safety system through a wire: in the event of an obstacle detection or in case of any problem while working, the system automatically stops the process.

Minimal lubrification system: The machine has a standard minimal lubrification system in kit with 2 nozzle and 3 l tank capacity. The minimal lubrication standard avoids the dispersion of refrigerant liquid typical in the use of emulsifiable oil, the life of the blade is not in any way affected.