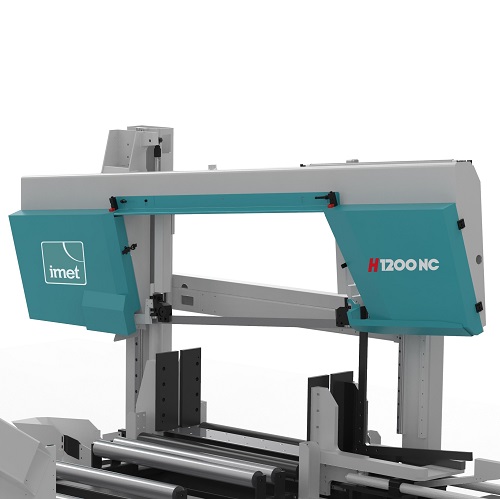

IMET – H800 – Semiautomatic Double Column Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | H800 |

Description

IMET – H800 – Semiautomatic Double Column Bandsaw

Semiautomatic bandsaws for straight cut

H800 is the semiautomatic double column bandsaw for straight cut (90°) that provides high working performances with reliable cutting quality and an optimized cutting process thanks to the 5° canted blade, easing the material penetration even on the biggest sizes. The machine is suitable for tubes, pipes, full materials and carpentry works.

TECHNICAL INFORMATION

| Cutting capacity at 90° | Round: 680mm Square: 640mm Rectangular: 820x610mm |

| Cutting capacity at 90° full material | 350mm |

| Bundle cutting capacity | 800x500mm MAX 50X50mm MIN |

| Blade motor | 5.5KW |

| Blade speed | from 15 to 100 m/min |

| Blade size | 7260x41x1.3mm |

| Blade tension | 2000kg/cm2 |

| Band inclination | 5° |

| weight | 3100kg |

| Size | 1550x3600x2700mm |

| Working table height | 800mm |

| Hydraulic unit motor | 0.75KW |

| Hydraulic unit tank capacity | 20l |

Working plate: H series bandsaws are equipped with a wide working plate that can fully support the material, allowing to have a stable and reliable cut.

Rigid sawframe: H 800 saws is electrowelded in steel with rigid tubolar section and big thickness to help reduce any vibration while cutting even the largest diameters. The massive structure also avoids binding or slowdowns of the sawing rates.

Mobile panel control: Semiautomatic bandsaws are equipped with mobile panel control and 10″ touch screen display with simple and intuitive interface that gives to the user full control and possibility to set and modify all the machine’s settings and functionalities.

Canted sawframe: The cutting process is optimized by the 5° canted blade that allows to ease the material penetration, reducing the band strain, helping save blade life and improving cutting performance even on full materials and big diameters and sections.

Blade tensioning: IMET bandsaws have a high blade tension (2000kg/cm2 on H 800 model) to increase the machine performance on every kind of material and section.

Smart-start and fast approach: H 800 and H 1200 recognise the start cut point thanks to a magnetic strip with encoder for material reading: the operator must set the material size on the panel control, the machine starts the automatic fast lowering of the sawframe up to the set value. This process allows to have a faster and easier approach to the material, helping saving time.

End cut: Operator can choose among different option for the end cut: sawframe rising while the blade is not working, with blade in function and end-cycle without moving the bow.

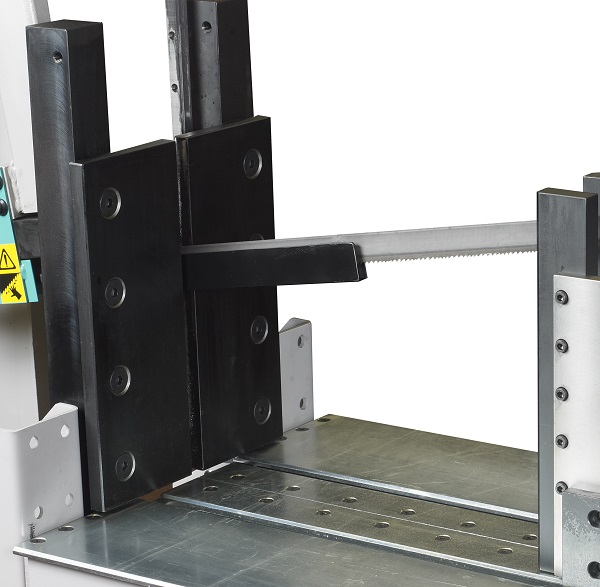

Blade guides: Registrable blade guides in metal pads and bearings. The mobile blade guide is automatically being kept next the cutting area.

Blade cleaning: The machine mounts a motorized cleaning brush with nylon teeth, allowing to remove residuals and remaining in the cutting area and on the blade.

Vice: H 800 mounts an hydraulic horizontal vice with full stroke so that the material is perfectly locked and ready to be cut.