IMET H601 – Semiautomatic Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | H601 |

Description

IMET H601 – Semiautomatic Bandsaw

Semiautomatic double column bandsaws for pipes

Semiautomatic double column bandsaws with hydraylic movement of the cutting saws. Machine has the possibility to cut from 0° to 60°to cute left. H 601 is the perfect working tool to cut pipes, bars and solid materials (up to 280mm on the round) and is suitable for carpentry works.

TECHNICAL INFORMATION

| Cutting capacity at 90° | Round: 510mm Square: 450mm Rectangular: 610x440mm |

| Cutting capacity at 45° | Round: 440mm Square: 440mm Rectangular: 440x450mm |

| Cutting capacity at 60° | Round: 260mm Square: 260mm Rectangular: 250x450mm |

| Cutting capacity at 90° with bundle | Max 600x250mm Min 150x50mm |

| Cutting capacity at 90° solid (C45) | 280mm (350mm with 41mm blade and 4KW motored.) |

| Blade size | 5320x34x1.1mm |

| Maximum opening of the vice | 620mm |

| Blade inclination | 6° |

| Blade motor | 3Kw |

| Blade speed | 15÷110 |

| Working plate height | 820mm |

| Hydraulic unit tank capacity | 20l |

| Cooolant tank capacity | 60l |

| Machine size | 1500x2850x2170mm |

| Weight | 1700kg |

Working area: Machine has a wide working area to fully support the material while cutting. The plate is supported by a central pivot with preloadedd bearings.

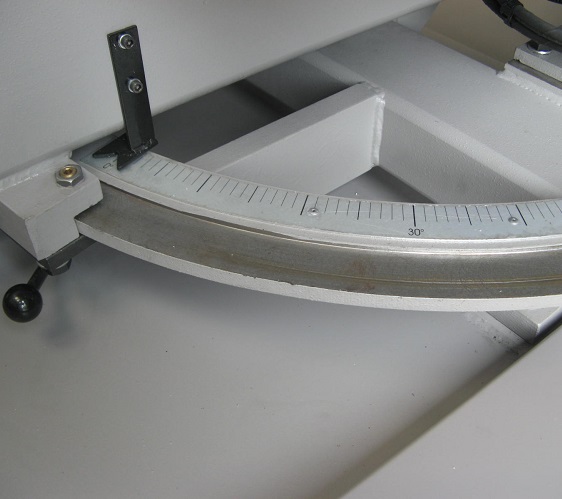

Graduated scale: H 601 worktable has a system with cutting grades reported on the plate that allows to always have the highest precision and accuracy while setting the cutting angle.

Steel sawframe: H 601 has a rigid steel electrowelded sawframe with tubolar section to have maximum stability while working. T Saw movement onto big size column through two recirculating ballscrews linear guides. To increase the cutting performance, the bandsaw has a very high blade tension (2000kg/cm2).

6° blade inclination: H 601 allows to have the hightest efficiency and high cutting performances even on big section thanks to the 6° blade inclination that ease the material penetration even on solids and full pieces and helps avoiding any vibration, binding or slowdown while working.

Blocking vice: It’s also present an hydraulic blocking vice sliding on chromed bar with 260mm height closing jaws.

Material detection device: To ease the fast approach of the saw blade to the material, the machine is equipped with an innovative mechanical material detection device which allows to easy set automatically the first cut point.

End-cut point: The machine is equipped with a control micro-switch on the mobile blade guide for the automatic detection of the end-cut point.

Horizontal supporting roll: The machine has a supplementary support roll placed on the loading side for a better support to the material even on bigger sizes. It’s also present, on the loading side, a predisposition for roller table.

Panel control: Stand-alone, the mobile panel control gives the operator full control of the cutting process, allowing to set all the main working parameters thanks to an easy interface.

Variable blade speed: The machine is equipped with ESC, electronic inverter for variable speed so that it’s suitable to cut different materials.