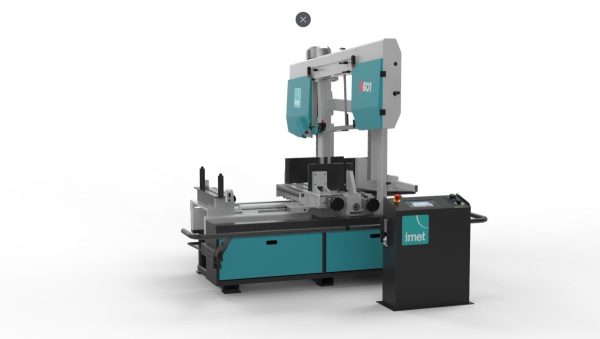

IMET – H601 NC – Automatic Double Column Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | H601 NC |

Description

IMET – H601 NC – Automatic Double Column Bandsaw

H 601 F500-1500 is the automatic double column bandsaw dedicated to cut carpentry profiles, tubes and solid materials. The machine can cut in automatic cycle up to 60° on the left and, thanks to its easy interface, 7″ touch screen display, it’s suitable to set up multiple cutting programs and length, while managing all main settings througth the CNC.

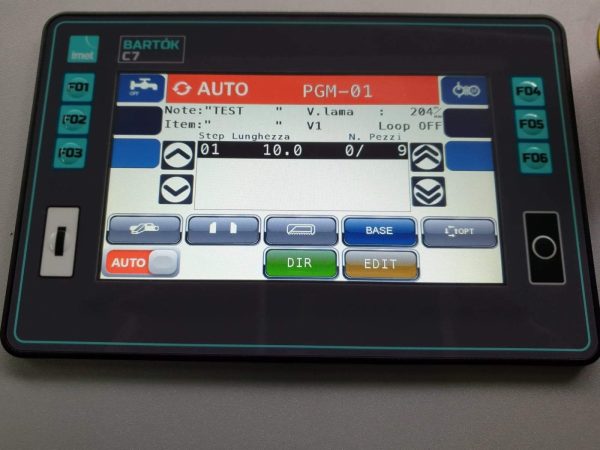

Easy-to-use interface and 7″ touch screen

H 601 NC has an easy and intuitive interface dedicate do optimise the user-experience: thanks the CNC system and 7″ touch screen display, the user can manage all the machine operative function, set up 99 cutting program and multiple cutting length on the same bar, set the number of feeder stroke, the number of pieces and blade speed. It’s also possible to do an auto diagnostic to detect errors.

Wide working area

The machine has a wide working table supported by a central pivot with preloaded bearings. Its present a graded scale on the plate to ease the user workflow and the highest positioning precision. When the machine is cutting at 0°, the plate mounts a supplementary grid to fully support the material: to use the graded scale and the cut different angles, the grid must be removed.

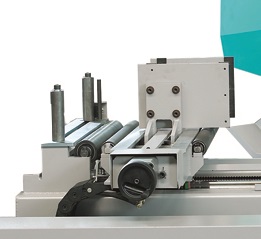

Material feeding

Feeder length is 500mm (available also 1500mm) with automatic stroke repetition, movement on 32mm diameter ball recycle ballscrews. Feeder allows to have a 30 mm of minimum cutting length and 100mm minimum scrap-end.

Precision

H 601 NC has a high positioning precision and stroke repetition thanks to the incremental screw with self-braking motor with inverter. The tolerance for every single feeder stroke is +/- 0.2mm on rectilinear bars.

Material loading

H601 NC F500 allows to load in the feeder even not rectilinear bars thanks to its innovative system which open both sides jaws to ease this process. The sawing machine is also equipped with an integrated loading roll in the front which allows to load even big section and big size profiles.

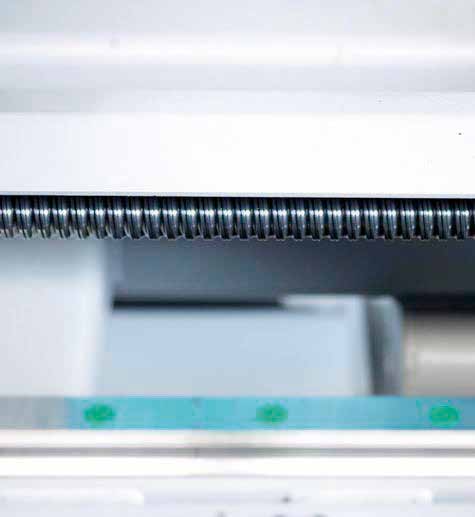

Rigid sawframe and performances

H 601 NC is equipped with an electro welded bow, great thickness, and tubular section to help reduce vibration, binding and slowing during the cutting process. Sawframe movement is perfectly balanced because is on linear guides and guaranteed by the large diameter of the hydraulic cylinder. Like all IMET bandsaws, also H 601 NC has a canted blade (5°) and high blade tension (2000kg/cm2) to reduce strain while cutting even on bigger section and full material.

Blade speed

The machine mounts an inverter ESC blade speed variator that allows to set and manage (via touch screen and interface) different speed so that it’s possible to cut multiple materials.

Material detect device

Mechanical material detect device allows to optimize the cutting process by easing the fast approach to the materials, automatically detecting the first cut point and helping to regulate the end cut.

TECHNICAL INFORMATION

| Cutting capacity at 90° | Round: 510mm Square: 450mm Rectangular: 610x440mm |

| Cutting capacity at 45° | Round: 440mm Square: 440mm Rectangular: 440x450mm |

| Cutting capacity at 60° | Round: 260mm Square: 260mm Rectangular: 250x450mm |

| Cutting capacity at 90° with bundle | Max 600x250mm Min 150x50mm |

| Cutting capacity at 90° solid (C45) | 280mm (350mm with 41mm blade and 4KW motored.) |

| Blade size | 5320x34x1.1mm |

| Maximum opening of the vice | 620mm |

| Blade inclination | 6° |

| Blade motor | 3Kw (Option 4Kw) |

| Blade speed | 15÷110 |

| Minimum scrap-end | 100mm |

| Feeder length | 550mm (option F1500) |

| Minimum cutting length | 30mm |

| Machine size (working table height) | 2650x2900x2170mm (820mm) |

| Weight | 2300kg |

![IMET – KTECH 352 – F1200 – Automatic bandsaw for structural steels [Made In Italy] IMET - KTECH 352 - F1200 - Automatic bandsaw for structural steels [Made In Italy]](https://www.delahenty.com.au/newwp/wp-content/uploads/2024/10/IMET-KTECH-352-F1200-MAXI-LINE-image01-300x300.jpg)