IMET – CUBO 300 NC BOX – Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | CUBO 300 NC BOX |

Description

IMET – CUBO 300 NC BOX – Bandsaw

Delahanty Machinery offers a range of bandsaws, circular saws and sawing machines. Contact us to discuss the most productive machine for your needs.

CUBO 300 NC BOX is the new IMET automatic sawing machine, part of the innovative CUBO series, products designed to optimise the user experience and guarantee the operator’s safety thanks to the barriers placed on the 4 sides of the machine. The 300 NC is equipped with numerical control, touch screen display and manual arc rotation and an automatic integrated feeder.

- CNC automatic bandsaw, hydraulically driven

- Mitre cutting from 0° to 45° left in automatic cycle and from 0° to 60° left in semiautomatic cycle

- CUBO 300-NC is an Industry 4.0 tool and has the possibility to use it remotely

- Easy stops at 0°, graduated plate to identify different angles.

- High blade tensioning 1700 kg / cm² to increase cutting accuracy and reduce cutting time.

- Up to 99 different cutting lengths and number of cuts can be memorised, with the possibility to repeat them more than once.

- CNC with programming of all operations; automatic calculation of the blade thickness.

- Machine status shown on display, including blade speed, piece counter, and working anomalies. The setting of the cutting lengths, minimal scrap-end 210 mm. Connection for loading table with 2 vertical rollers, unloading slide, connection for unloading table for cutting pieces.

- Main switch with minimum tension coil, emergency button, thermic and magnetic motor protection.

- Cutting capacity: round till 255 mm., square till 240 mm. and rectangular till 300×180 mm.

- The modem for Industry 4.0, teleservice and remote control is supplied as an optional.

CUBO Series

CUBO is the line of automatic saws developed to optimize the user experience thanks to the introduction of various stylistic and functional innovations. Ease of use and safety for the operator during the cutting make it the ideal work tool for any environment.

Touch screen display

Through the 7-inch touch screen display (with simple and intuitive graphics to optimize the user-experience it is possible to set and control all the machine parameters; the interface allows you to set up cutting projects with different quantities and lengths on the same bar and visualize any errors during the cutting process

Numerical control

It allows to store up to 99 cutting programs by automatically calculating the thickness of the blade, total number of pieces to be cut, cutting length settings, and running of the automatic cutting cycle.

Automatic material detection

CUBO 300 NC is equipped with an automatic material detection device to optimize the cutting process facilitating the approach to the material and adjusting the end cut by means of a microswitch.

Security and accessibility

CUBO 300 NC has an integrated protection system on the 4 sides of the machine to ensure maximum safety for the operator during the cutting process. The protection system does not prevent complete access to the internal parts of the machine for any maintenance needs.

Feeder carriage

The feeder carriage has a maximum stroke of 515mm. The sliding takes place on chromed bars with high precision of the positioning due to the incremental feeding on recirculating ball screw by self-braking electric motor and inverter

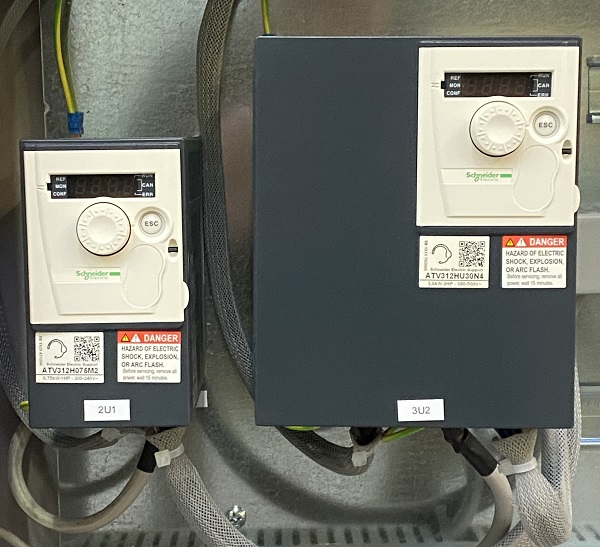

Speed variator

The versions of the numerically controlled CUBO (CUBO 300 NC and CUBO 300 NC FLAT) are equipped with an inverter speed variator as standard.

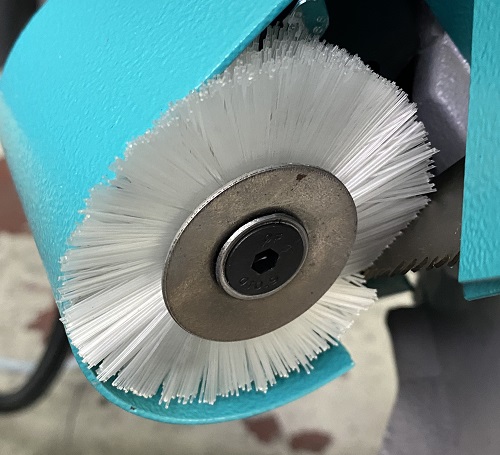

Blade cleaning brush

CUBO 300 NC mounts a motorized nylon blade cleaning brush for maximum efficiency during the cutting process.

![IMET – KTECH 352 – F1200 – Automatic bandsaw for structural steels [Made In Italy] IMET - KTECH 352 - F1200 - Automatic bandsaw for structural steels [Made In Italy]](https://www.delahenty.com.au/newwp/wp-content/uploads/2024/10/IMET-KTECH-352-F1200-MAXI-LINE-image01-300x300.jpg)