IMET – CUBO 300 E FLAT Bandsaw

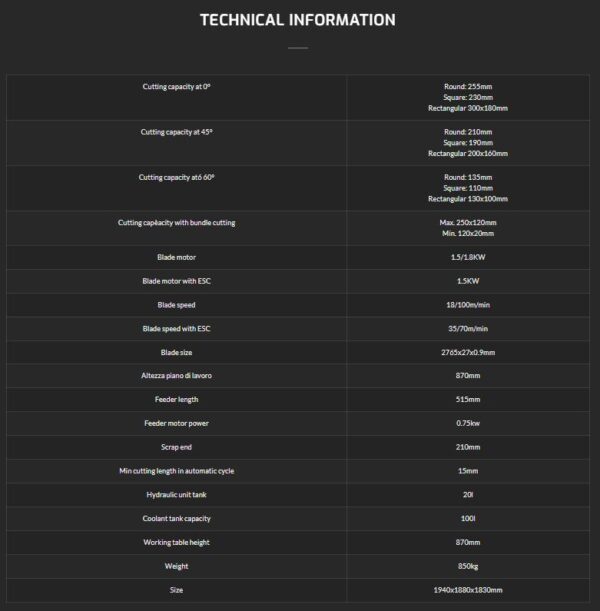

Specifications

| Make | IMET |

|---|---|

| Model | CUBO 300 E FLAT |

Description

IMET – CUBO 300 E FLAT Bandsaw

Delahenty Machinery offers a range of bandsaws, circular saws and sawing machines. Contact us to discuss the most productive machine for your needs.

Automatic bandsaw with electronic control

CUBO 300 E FLAT is the electronic automatic bandsaw, is an innovative working tool intended to cut medium size tube, profiles and bars. The machine allows to cut one cutting length at a time by setting the measure and the position with the manual handler with digital reading. The machine has a manual rotation of the bow and automatic material feeder.

- Electronic automatic bandsaw, hydraulically driven; mitre cutting from 0° to 45° left in automatic cycle and up to 60° left in semiautomatic cycle.

- Cast iron saw frame with tubular section.

- Adjustment of the blade tension from the front side of the sawframe, checked by an endstroke.

- Blade guides with hard metal pads, additional bearing for blade alignment.

- Feeder with 300 mm opening, maximum single stroke 515 mm, minimum stroke 4 mm, selection of the number of cuts (1-9999) and feeder strokes (1-29) by means of the keyboard.

- Manual selection of the cutting length with digital reading and decimal accuracy.

- Cutting capacity: round till 255 mm., square till 240 mm. and rectangular till 300×180 mm.

Innovative CUBO series

CUBO Series introduces a cluster of innovation about design and new functionalities: CUBO range aims to optimise our customers user experience safeguarding the security of the machine operator during the cutting process, making CUBO the ideal working tool for every professional environment and metal carpentry.

Automatic material detection

CUBO Series bandsaws has an automatic material detection system thanks to a mechanical device (position sensor) that allows the sawframe to lower quickly toward the material, detecting the automatically the start-cut point and micro-switch to control the end cut point.

Cutting length

The machine is equipped with electronic control which manual selection of the cutting length with digital reading: after setting the required length and the number of cuts, a trim cut is performed, then the bar is cut till the end

Programming via keyboard

Programming of all operation by means of the keyboard: through the machine display is also possible to manage blade life and speed, pieces counter, cycle time, motor absorption and working anomalies. Through the panel control is also possible to set the number of cuts.

Feeder system

CUBO 300 E FLAT is equipped with a feeder system with floating adjustment to ease the loading of material non perfectly straight and 300 mm opening; the maximum single stoke is 515 mm while the minimum is 4 mm

Rigid sawframe

Cutting performances are guaranteed by the cast-iron sawframe with tubular section and high blade tension (1700 kg/cm2) that reduce the strain on the blade, helping to optimise cutting times even on bigger and wider sections.

Blade protection

A carter protects the blade, allowing to have easy access for maintenance when needed; a system with blade guides with hard pads, additional lateral bearings provides for the perfect alignment of the blade. A motorised metal brush keeps the blade clean and provide to remove any residual while working.

![IMET – KTECH 352 – F1200 – Automatic bandsaw for structural steels [Made In Italy] IMET - KTECH 352 - F1200 - Automatic bandsaw for structural steels [Made In Italy]](https://www.delahenty.com.au/newwp/wp-content/uploads/2024/10/IMET-KTECH-352-F1200-MAXI-LINE-image01-300x300.jpg)