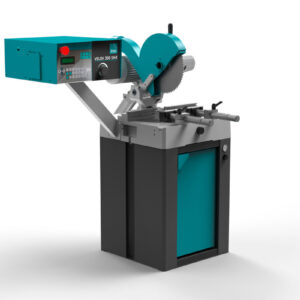

IMET – BS 350 SHI – Semiautomatic Pivotal Bandsaw to Cut Steel

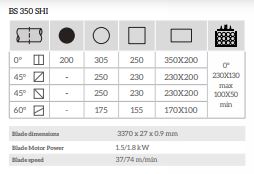

Specifications

| Make | IMET |

|---|---|

| Model | BS 350 SHI |

Description

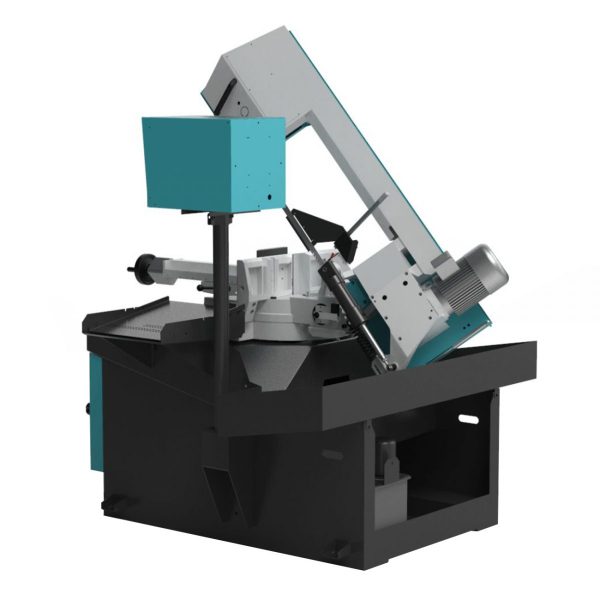

IMET – BS 350 SHI – Semiautomatic Pivotal Bandsaw to Cut Steel

Semi automatic two way mitre with full hydraulic control

The BS 350 SHI is a heavy-duty hydraulic, semi-automatic bandsaw with mitre cutting capabilities ranging from 0° to 60° on the right and from 0° to 45° on the left.

It is highly recommended for production situations, particularly when cutting square sections or flat bars. This is due to its unique below centre pivot point, which causes the blade to be inclined at the end of the cut, offering the line of least resistance for these materials. The advantages of this design are faster cut times, longer blade life, a wider range of materials that can be cut with each blade pitch, and reduced stress on the machine components. It is important not to underestimate the significance of this feature, combined with the robust construction and high-quality components, all of which contribute to making the BS350 a leading product in its class.

Features:

- Material height sensor and rapid approach feature

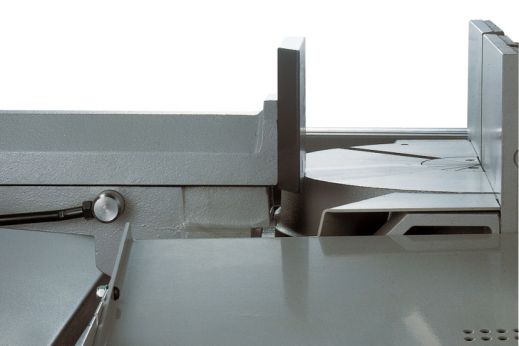

- Carbide blade guides and a blade cleaning brush

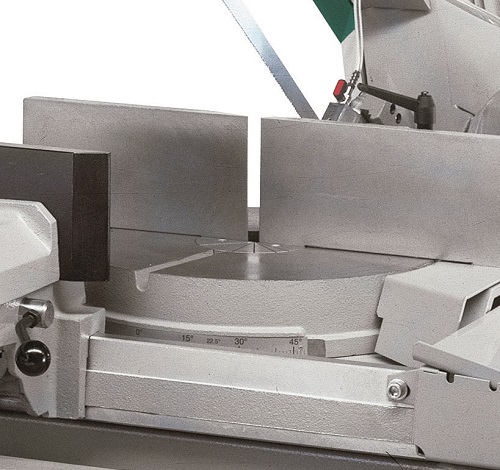

- Positive mitre locations at 0°, 45°, and 60°

- Automatic saw head return after each cut

- Electric flood coolant system

- Rotating cutting table

- Variable downfeed control

- Blade inclined at the end of the cut (refer to the information below)

- AMP meter indicating the blade condition

- Machine status indicator for monitoring

- Blade tension adjustment

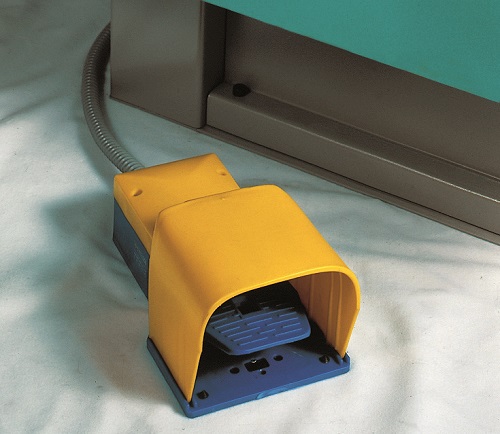

- Full hydraulic control

- Hydraulic vice