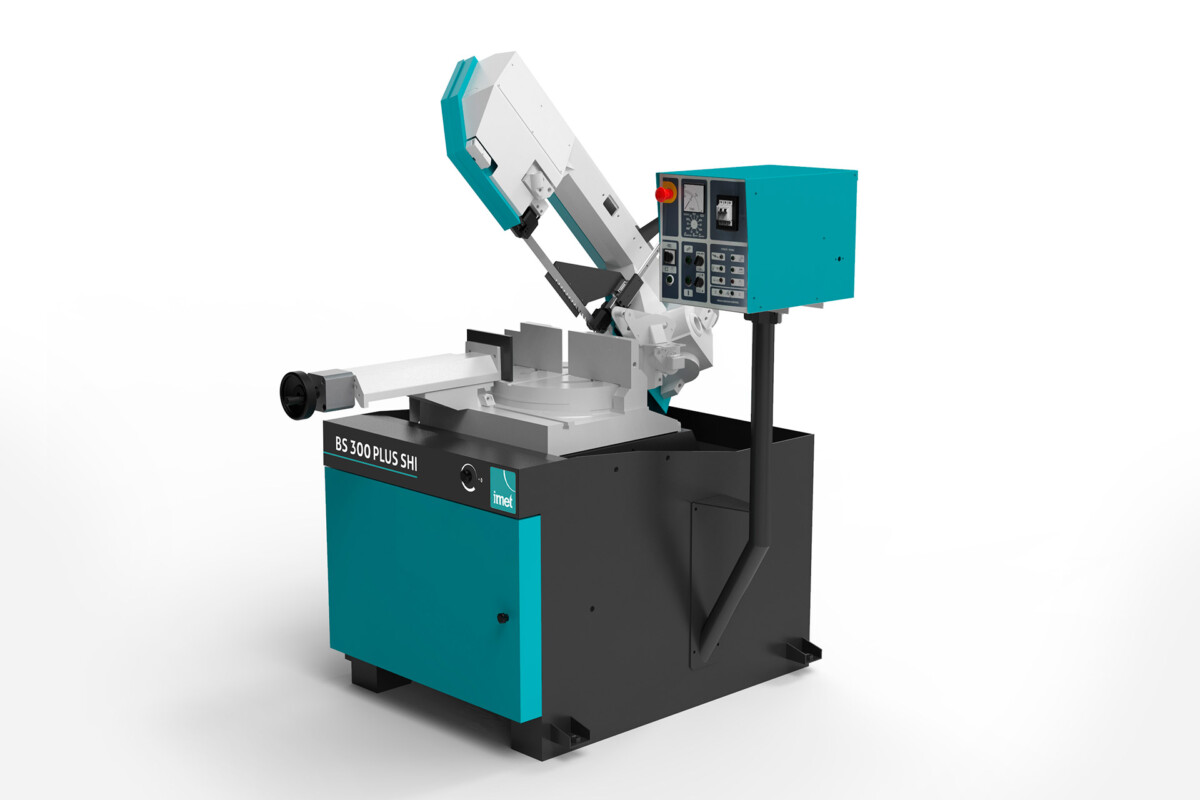

IMET – BS 300 PLUS SHI – Semiautomatic Bandsaw

Specifications

| Make | IMET |

|---|---|

| Model | BS 300 PLUS SHI |

Description

IMET – BS 300 PLUS SHI – Semiautomatic Bandsaw

Semiautomatic Bandsaw for small, medium production

BS 300 PLUS SHI is the semiautomatic bandsaws intended to cut both left (up to 60°) and right (from 0° to 45°). The machine is a suitable working tool for small and medium batch production for mechanics and steelwork.

Technical Information

| Cutting capacity at 90° | Round 255 mm. Square 230 mm. Rectangular 300x180mm |

| Cutting capacity at 45° right | Round 210 mm. Square 190 mm. Rectangular 200x180mm |

| Cutting capacity at 45° left | Round 180 mm. Square 160 mm. Rectangular 180x100mm |

| Cutting capacity at 60° left | Round 135 mm. Square 110 mm. Rectangular 130x100mm |

| Cutting capapcity with bundle device | 250x130mm 85x10mm |

| Maximum capacity for full materials | 180mm |

| Blade size. | 2765x27x0,9 |

| End-cutting bandsaw inclination | 3° |

| Blade motor | 1,5/1,8 kw |

| Blade speed | 35/70 15÷110 m/min |

| Hydraulic unit motor power | kw 0,37 |

| Hydraulic united tank | Lt 12 |

| Coolant tank | Lt 20 |

| Size – Weight | 1230x1700x1750 mm 412kg |

| Working table height | 940 mm |

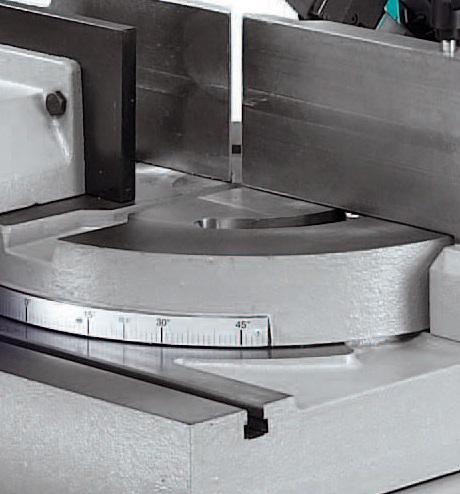

Wide working area : BS 300 PLUS is equipped with a wide diameter working area and a system of automatic easy stops at 0°, 45° and 60° left and 45° right with graduated plate to identify and set different angles.

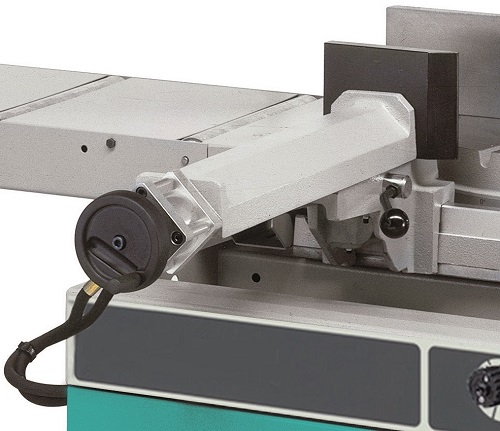

Opening vice: The vice has adjustable guides, free to move alongside the worktable, with rapid approaching and camping.

Rigid sawframe: Machine sawframe is rigid cast-iron with tubolar section, 320 mm pulleys, high blade tension at 1700 kg/cm2 and to avoid an excessive strain on the blade with frontal regulation and microswitch conroller.

Blade protection: A carter protect che blade, allowing to have easy access for maintentance when needed; a system with blade guides with hard pads, additional lateral bearings provides for the perfect allignment of the blade

Easy to use: Safe starting through the button on the handle with warning light to inform the use about the correct machine functioning. Coolant-tank and electropump are placed inside the floor stand.

Electromic inverter (Optional): If required, the electronic inverter for variable blade speed allows the operator via keyboard to adjust the machine to be able to cut a wide range of materials and different sections. The change of speed is via inverter and it does not affect the power of the engine even at low speeds.