Hornet HD CNC Plasma Cutter

Specifications

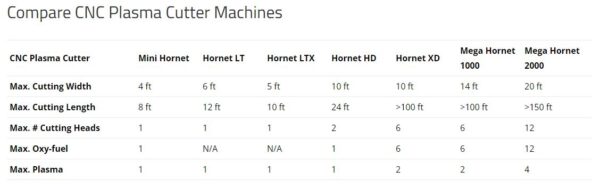

| Make | Hornet |

|---|

Description

Hornet HD CNC Plasma Cutter

The Hornet HD CNC plasma cutter is the most cost-effective plasma table on the market.

The Hornet HD CNC plasma cutter delivers maximum productivity, helping you get more done in less time.

The Hornet HD includes a Hypertherm PC based CNC control, heavy-wall steel tubing machine frame and gantry beam, precision ground linear rails on both the X & Y axis, powerful AC servo motors and low back-lash planetary gear boxes.

The gantry beam and cross axis carriage ride on precision ground linear tracks to deliver premium motion control and accuracy.

The Hornet HD features the Hypertherm XPR Series power source, which includes the unmatched precision of True Hole™, the elimination of secondary processing provided by True Bevel™ technology, with increased productivity and slashed operating costs from the advanced cut speed of the XPR300™.

Hornet HD Cutting Sizes

The Hornet HD CNC plasma machine is available in 5.0′ (1.5 m) , 6.6′ (2.0 m), 8.2′ (2.5 m) and 10.0′ (3.0 m) effective cutting widths. Plasma tables are available with 12′ (3.7 m), 20′ (6.1 m) or 24′ (7.3 m) effective cutting lengths.

Standard Features of the Hornet HD CNC Plasma Cutter

- Hypertherm Plasma Edge Connect CNC Control with Phoenix CNC software

- Heavy wall steel tubing machine frame and gantry beam

- Fabricated end trucks

- 2100 IPM (53.3 mm/min) rapid traverse speed

- Tucked 30 mm linear guides on main rail axis (X)

- Dual 20 mm linear guides on cross axis (Y)

- Alloy steel pinion gears

- 3/4” (19.5 mm) helical gear rack

- Planetary gear heads

- Flexible cable carriers on both X & Y axis

- Tool carriage for one plasma & one oxy-fuel torch station

Options

- Remote CNC Control Pedestal

- Plasma Cutting Systems up to 400 Amps

- SENSOR Torch Height Control Interface

- RSVS-200 Plasma Torch Lifter

- Plasma Torch Collision Mount

- Manual Bevel Attachment

- Plasma Roller Ball Floating Head

- Basic Oxy-Fuel Gas Manifold

- Air Scribe Marker station

- Automatic Lubrication Systems

- AeroCLEAN Multi Zone Down Draft Air Table

- HydroClean CNC Plasma Cutting Water Table

- Dust Collection Systems

- CAM Software

Phoenix CNC Control Software

- Microsoft Windows 10 – embedded version.

- Hypertherm Phoenix CNC software.

- Remote Help via the internet.

- Cut Pro Wizard

- Customisable process tables.

- CAD file to CNC converter & row and column nesting.

- Enlarged screen elements with pop-up keyboards and number pads.

- Shape library with 68 shapes, allowing more than 300 parts to be programmed.

- Shape Wizard allows to construct / edit parts on screen

- Dynamic kerf compensation.

- Restart cutting ahead or behind current position or move to exact pierce number.

- Move forward or backward on path.

- Watch windows for speed, position, consumable life, process data, and status messages.

- Online Help function

Plasma THC Technology

SENSOR THC electronics and Hornet Cutting Systems RSVS-200 Lifter:

- Delivers Hypertherm Rapid Part Technology with ProNest and Collision Avoidance

- 600 IPM (15 m/min) vertical positioning speed

- Pierce height sensing using Ohmic or position error stall detection

- Maintains torch to plate height during cut via voltage regulation

- 8″ (200 mm) stroke travel for torch positioning

- 50-300 VDC Arc Voltage Range in .1 volt increments

- Pneumatic plasma torch collision mount with E-Stop to CNC

THC Control Parameters:

- Transfer height

- Pierce height

- Pierce time

- Cutting height

- Cutting voltage

- Retract height after cut