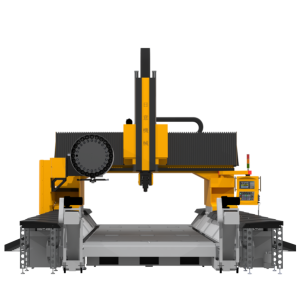

GEMMA – Cutmatic – CNC Machining Centre

Specifications

| Make | GEMMA |

|---|---|

| Model | Cutmatic |

Description

GEMMA – Cutmatic – CNC Machining Centre

The GEMMA Cutmatic CNC Machining Centre is a cutting-edge solution designed for high-precision and efficient machining.

Features:

- Advanced CNC Control System:

- Precision and Flexibility: The Cutmatic is equipped with a state-of-the-art CNC control system that offers precise control over machining operations. This system supports complex programming, automated processes, and real-time adjustments, ensuring high accuracy and flexibility.

- High-Speed Spindle:

- Enhanced Productivity: The machine features a high-speed spindle capable of rapid cutting and high-quality finishes. This allows for faster machining of various materials, improving overall productivity and reducing cycle times.

- Multiple Axis Capabilities:

- Complex Machining: The Cutmatic typically includes multi-axis functionality, allowing for intricate and complex machining tasks. This multi-axis capability enables precise operations such as drilling, milling, and contouring with minimal manual intervention.

- Automatic Tool Change System:

- Efficiency: The integrated automatic tool changer facilitates quick and seamless transitions between different tools, reducing downtime and speeding up production. This feature is essential for handling diverse machining tasks without manual tool changes.

- Large Work Envelope:

- Versatility: With a substantial work envelope, the Cutmatic can accommodate larger and more complex workpieces. This versatility makes it suitable for a wide range of applications, from small, detailed parts to larger components.

- High Precision Linear Guides:

- Accuracy: The machine utilizes high-precision linear guides for smooth and accurate movement along the axes. This contributes to superior machining quality and the ability to maintain tight tolerances.

- User-Friendly Interface:

- Ease of Use: The Cutmatic features an intuitive touchscreen interface that simplifies programming and machine operation. Operators can easily input parameters, monitor the machining process, and make real-time adjustments with minimal training.

- Robust Construction:

- Durability: Built with high-quality materials and a solid frame, the Cutmatic is designed to withstand heavy usage and provide long-term reliability. This ensures consistent performance and reduces maintenance needs.

- Integrated Safety Features:

- Safe Operation: The machine includes various safety features, such as emergency stops, safety guards, and sensors, to ensure a safe working environment and protect operators during operation.

Benefits:

- High Precision and Quality:

- The advanced CNC control and precision components deliver highly accurate machining with excellent surface finishes. This is crucial for producing high-quality parts that meet strict specifications.

- Increased Productivity:

- High-speed spindle, automatic tool changing, and efficient multi-axis capabilities contribute to faster machining processes and shorter production cycles. This increases overall productivity and allows for handling both high-volume and custom jobs.

- Versatility:

- The large work envelope and multi-axis capabilities enable the Cutmatic to handle a wide range of machining tasks and materials. This versatility makes it suitable for various industries and applications, enhancing your operational flexibility.

- Cost Efficiency:

- By reducing cycle times, tool change times, and material waste, the Cutmatic helps lower production costs and improve your return on investment. The durability and low maintenance requirements also contribute to long-term cost savings.

- Ease of Operation:

- The user-friendly interface and intuitive programming simplify machine operation, reducing the learning curve for new operators and increasing overall workflow efficiency. This can lead to fewer errors and higher operational efficiency.

- Enhanced Safety:

- Integrated safety features protect operators and create a safer working environment, minimizing the risk of accidents and ensuring compliance with safety regulations.

- Long-Term Reliability:

- The robust construction and high-quality components ensure that the Cutmatic provides reliable performance over the long term, reducing the need for frequent repairs and maintenance.

In summary, the GEMMA Cutmatic CNC Machining Centre offers a blend of precision, efficiency, and versatility that makes it an excellent choice for any machining operation. Its advanced features and benefits help enhance production quality, improve productivity, and ensure long-term reliability, making it a valuable asset for any workshop or manufacturing facility.