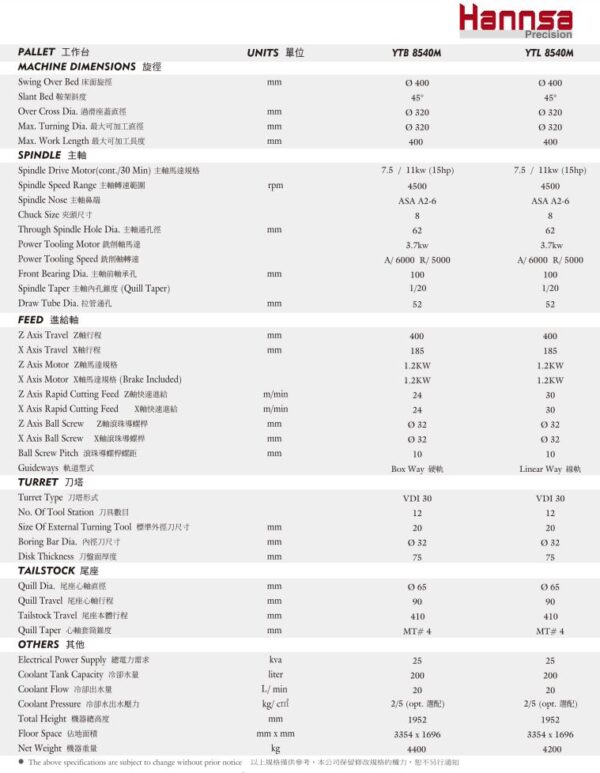

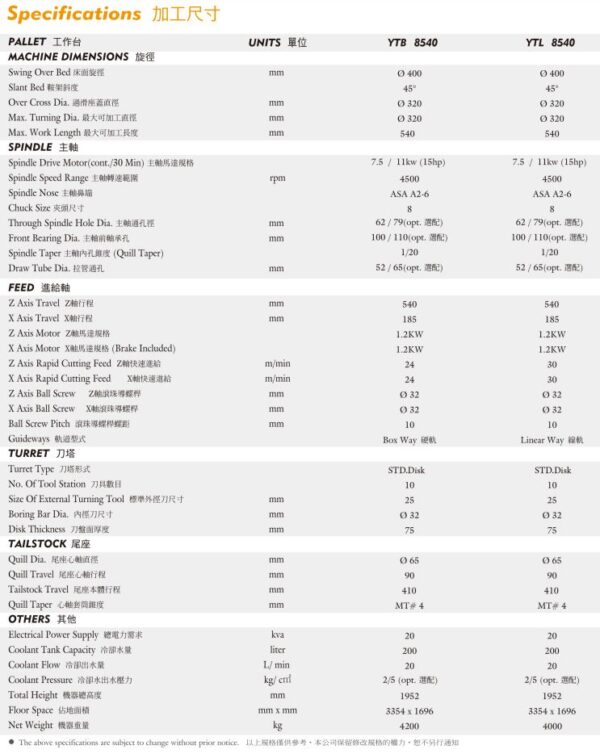

HANNSA – CNC Lathe / Linear Way Series

Specifications

| Make | HANNSA |

|---|---|

| Model | CNC |

Description

HANNSA – CNC Lathe / Linear Way Series

The HANNSA CNC Lathe from the Linear Way Series is a top-tier choice for anyone looking to enhance their machining capabilities with cutting-edge technology. Here’s a compelling overview of its features and benefits:

Features:

- Linear Way Technology:

- Precision and Smoothness: The Linear Way Series incorporates linear guideways, which provide exceptional smoothness and accuracy. This technology minimizes friction and wear, resulting in higher precision and a longer lifespan for the machine.

- Advanced CNC Controls:

- User-Friendly Interface: Equipped with sophisticated CNC controls, the HANNSA lathe offers a user-friendly interface that simplifies programming and operation. It allows for complex machining tasks to be executed with ease and precision.

- High-Speed Spindle:

- Enhanced Productivity: The lathe features a high-speed spindle capable of handling a wide range of materials. This enables faster cutting speeds and reduces machining time, enhancing overall productivity.

- Rigid Machine Structure:

- Stability and Durability: Designed with a robust and rigid structure, the HANNSA CNC Lathe ensures stability during operation, which contributes to the accuracy and quality of the finished parts.

- Large Work Capacity:

- Versatility: With a generous work envelope, the lathe can accommodate larger and more complex workpieces. This versatility makes it suitable for various applications, from small components to larger parts.

- Automatic Tool Changer:

- Increased Efficiency: The inclusion of an automatic tool changer streamlines the machining process by reducing manual tool changes, which speeds up production and minimizes downtime.

- High-Precision Ball Screws:

- Accuracy: The use of high-precision ball screws ensures accurate positioning and movement, which is crucial for achieving tight tolerances and high-quality finishes.

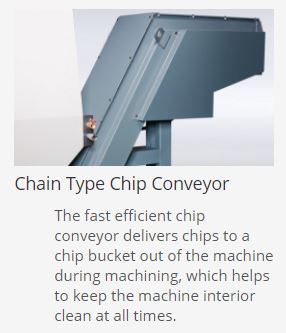

- Chip Removal System:

- Clean Operation: An efficient chip removal system helps maintain a clean working environment and prevents chips from interfering with the machining process, ensuring consistent performance.

Benefits:

- Enhanced Precision and Quality:

- The linear guideways and high-precision components result in superior accuracy and surface finish, which is critical for producing high-quality parts that meet stringent specifications.

- Increased Productivity:

- Faster spindle speeds and automated features like the tool changer contribute to shorter cycle times and higher production rates, making it ideal for both small-batch and large-scale production runs.

- Cost Efficiency:

- By reducing setup times, manual labor, and maintenance needs, the HANNSA CNC Lathe helps lower overall operational costs and improve your return on investment.

- Versatility:

- The ability to handle various workpieces and materials means you can tackle a wide range of projects without needing multiple machines, increasing your shop’s flexibility and capability.

- Reliability and Longevity:

- The machine’s rigid structure and high-quality components ensure long-term reliability and durability, reducing the likelihood of unexpected breakdowns and maintaining consistent performance.

- Ease of Use:

- The intuitive CNC controls and automation features make it easier for operators to achieve complex machining tasks, even with minimal training, which enhances overall workflow efficiency.

- Improved Safety:

- Advanced safety features and a well-designed chip removal system help create a safer working environment, minimizing risks associated with machining operations.

In summary, the HANNSA CNC Lathe from the Linear Way Series is a state-of-the-art machine designed to deliver exceptional precision, productivity, and versatility. Whether you’re a high-volume manufacturer or a precision-focused shop, its advanced features and benefits make it a valuable addition to any machining operation.