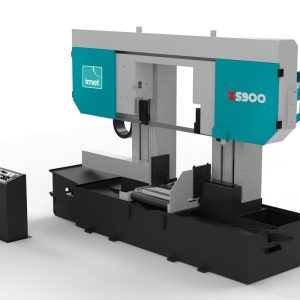

CHENLONG – GZ-4250H – Semi-Automatic Band Saw Machine

Specifications

| Make | CHENLONG |

|---|---|

| Model | GZ-4250H |

Description

CHENLONG – GZ-4250H – Semi-Automatic Band Saw Machine

Automatic Horizontal Band Saw Machine GZ4250H is mainly suitable for sawing profiles, bundled materials, etc. it has the advantages of narrow sawing gap, material saving, energy saving, high sawing precision, convenient operation and high production efficiency.

- Automatic Horizontal Band Saw Machine Is Specially Suitable For Sawing Pipes In Bundle.

- The Bundle Cutting Size Could Be 500×500mm

- Profiles Are Also Suitable

The speed of the driving wheel is adjusted by the belt pulley. By changing the belt position at the belt pulley, 4 different blade line speeds can be obtained to meet the sawing of different materials

The clamping of the automatic horizontal band saw machine GZ4250H adopts hydraulic vise clamping. A set of hydraulic vise is designed behind the saw blade. The oil cylinder adopts the structure of the screw cylinder. Move the movable vise to be 20mm away from the workpiece, and then the movable vise can be driven by the hydraulic cylinder to clamp the workpiece.

The third clamping device (optional)

Specifications

| Product Name | Automatic Horizontal Band Saw Machine | |

| Brand | CHENLONG | |

| Model | GZ4250H | |

| Maximum Cutting Size (Round) | 500mm | |

| Maximum Cutting Size (Quadrate) | 500×500mm | |

| Blade Line Speed | 40/55/70/90 m/min | |

| Blade Size | 41×1.3×5700 mm | |

| Blade Guides | Carbide And Bearing Blade Guides | |

| Blade Cleaning | Wire Brush & Flood Coolant | |

| Blade Tension | Manual | |

| Motors | Main Motor | 5.5kw |

| Hydraulic Motor | 1.5kw | |

| Water Pump Motor | 120w | |

| Multiple Feeding | 500mm×10Times | |

| Work Vise Control | Hydraulic | |

| Machine Size(L×W×H) | 2650×2225×1950 | |

| Standard Equipment: | ||

| 1. Blade Cleaning Brush. | ||

| 2. Working Light. | ||

| 3. Roller Table 1pcs (About 60cm ) | ||

| 4. One Piece Of Bi-metal Saw Blade. | ||

| 5. One Set Of Tools With Tool Box | ||

| 6. NC Control | ||

| 7. Bundle Cutting Device | ||

| Optional Equipment: | ||

| 1. Extra Common Roller Table | ||

| 2. The Third Clamping Device | ||