CHENLONG – GZ4243 – Fully Automatic Horizontal Bandsaw Machine

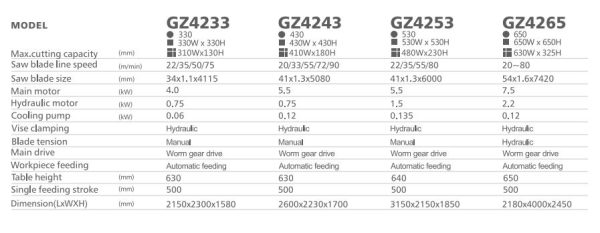

Specifications

| Make | CHENLONG |

|---|---|

| Model | GZ4243 |

Description

CHENLONG – GZ4243 – Fully Automatic Horizontal Bandsaw Machine

- Fully Automatic Horizontal Bandsaw Machine GZ4243 Is Upgraded From Model GZ4240.

- Cutting Range 430×430mm

- Cost-effective Bandsaw Machine

Specifications

- Maximum Cutting Size (Round): 430mm

- Maximum Cutting Size (Quadrate): 430×430mm

- Blade Line Speed: 20/32/55/72/90 m/min

- Blade Size: 41×1.3×5080 mm

- Blade Guides: Carbide And Bearing Blade Guides

- Blade Cleaning: Wire Brush & Flood Coolant

- Blade Tension: Manual

- Multiple Feeding: 500mm×10Times

- Work Vise Control: Hydraulic

- Machine Size(L×W×H): 2350×2500×1700

Motors:

- Main Motor: 5.5kw

- Hydraulic Motor: 0.75kw

- Water Pump Motor: 120w

Standard Equipment:

- Blade Cleaning Brush.

- Working Light.

- Roller Table 1pcs (About 60cm )

- One Piece Of Bi-metal Saw Blade.

- One Set Of Tools With Tool Box

- NC Control

- Bundle Cutting Device

Optional Equipment:

- Extra Common Roller Table

Machine Information

- This Bandsaw Machine Is An Ideal Equipment For Sawing Of Small And Medium-sized Bars, Tubes And Plates, And Can Be Adapted To Sawing Of Various Ferrous Materials. The Machine Tool Has The Characteristics Such As Cutting With High Efficiency, Saving Energy, Narrow Cutting Gap, Saving Material, And Simple Operation.

- Fully Automatic Horizontal Bandsaw Machine GZ4243 Adopts A Double-column Structure To Ensure The Reliability, Stability And Advancement Of The Structure. The Functions Of Each Part Have Margins, And At The Same Time, It Also Ensures High-quality Sawing Accuracy.

- The Clamping Vise Of Fully Automatic Horizontal Bandsaw Machine Moves On The Round Guide Rail Under The Action Of The Hydraulic Feeding Cylinder. The Feeding Length Is Detected By Grating Scale. The Single Feeding Stroke Is 500mm. It Can Do Multiple Feeding. The Fixed Vise Of The Feeding Table Has A Micro-movement Function. When The Feeding Table Retreats, The Fixed Vise Moves Back 5mm To Prevent Contact With The Material And Cause Inaccurate Feeding.

- In Order To Facilitate The Bundle Cutting Of Small-sized Bars, An Upper Pressure Cylinder Is Installed Above The Main Vise And The Feeding Vise, And Its Action Is Consistent With The Horizontal Clamping Action Of The Relative Vise, So As To Realize The Bundle-cutting Of Small-sized Materials.

![IMET – KTECH 352 – F1200 – Automatic bandsaw for structural steels [Made In Italy] IMET - KTECH 352 - F1200 - Automatic bandsaw for structural steels [Made In Italy]](https://www.delahenty.com.au/newwp/wp-content/uploads/2024/10/IMET-KTECH-352-F1200-MAXI-LINE-image01-300x300.jpg)