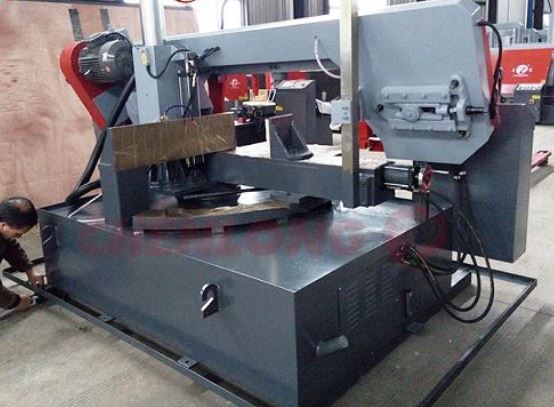

CHENLONG – G4240/70/Z – Semi-Automatic Mitre Band Saw Machine

$33,450.00

View BrochureSpecifications

| Make | CHENLONG |

|---|---|

| Model | G4240/70/Z |

Description

CHENLONG – G4240/70/Z

Semi-Automatic Mitre Band Saw Machine: From $33,450+GST

Metal Angle Cutting Band Saw Machine

- Metal Angle Cutting Band Saw Machine G4240/70Z Is A Double Column Type Semi-Automatic Machine, Cutting Range Is 0~45 Degree.

- Angle Turning Is Manually Controlled

- It Is Has Five Different Line Speeds

Specifications

- Maximum Cutting Size (0°Round): 400mm

- Maximum Cutting Size (0°Quadrate): 400×700mm

- Maximum Cutting Size (45°Round): 400mm

- Maximum Cutting Size (45°Quadrate): 400×400mm

- Blade Line Speed: 20/30/43/54/65 m/min

- Blade Size: 41×1.3×5500 mm

- Blade Guides: Carbide And Bearing Blade Guides

- Blade Cleaning: Wire Brush & Flood Coolant

- Blade Tension: Manual

- Work Vise Control: Hydraulic+Screw

- Machine Size(L×W×H)mm: 2650×1800×1950

Motors

- Main Motor 4kw

- Hydraulic Motor 0.75kw

- Water pump Motor 60w

Standard Equipment:

- Blade Cleaning Brush.

- Working Light.

- Roller Table 1pc(about 80cm)

- One Piece Of Bi-metal Saw Blade.

- One Set Of Tools With Tool Box

Optional Equipment:

- Extra Common Roller Table

Machine Information

- This metal angle cutting band saw machine adopts a double-column structure to ensure the reliability, stability and advancement of the structure.

- It is mainly used for Aagle sawing of profiles. The saw frame can rotate 0-45° around the rotation center under the drive of the screw rod. It has the characteristics of high cutting efficiency, energy saving, narrow saw gap, material saving, and simple operation.

- The main drive system of the metal angle cutting band saw machine is composed of a worm gear box, a driving wheel, a pulley, etc. The worm gear box and the driving wheel are directly connected, the transmission is stable and without impact. The speed of the driving wheel is adjusted by the belt pulley, five different cutting line speeds can be obtained to meet the sawing of different materials.

- The rotation of the machine is manually driven, and the angle is measured by the alignment method of the scale line. The rotating seat is rotated by a manual control screw. When the specified angle is reached and aligned with the scale line, the rotating seat is manually locked with screws.