CHENLONG – Fully Automatic Miter Cutting Band Saw Machine CH-300SA

Specifications

| Make | CHENLONG |

|---|---|

| Model | CH-300SA |

Description

This machine is mainly used for sawing small and medium-sized round pipes, square steel pipes, profiles, etc. In addition to 0° sawing, it also can do 0-45° angle sawing. The feeding adopts hydraulic automatic feeding, automatic length fixing, Plc programmable control, touch screen operation, and grating ruler detects the sawing length. It has the advantages of narrow sawing gap, material saving, energy saving, high sawing precision, convenient operation and high production efficiency.

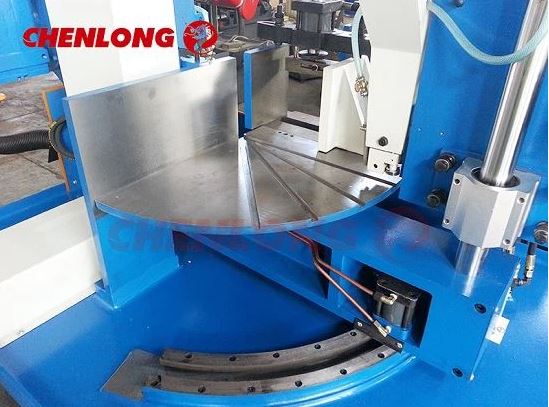

1. Angle Horizontal Metal Band Saw Machine CH-300SA Is A Double Column Type Fully Automatic Machine, Angle Cutting Range Is 0~45 Degree.

2. Angle Turning Is Automatically Controlled.

3. Automatic Feeding And Cutting.

PRODUCT INTRODUCTION

Specifications

| Product Name | Angle Horizontal Metal Band Saw Machine | |

| Brand | CHENLONG | |

| Model | CH-300SA | |

| Maximum Cutting Size (0°Round) | 300mm | |

| Maximum Cutting Size (0°Quadrate) | 300×350mm | |

| Maximum Cutting Size (45°Round) | 230mm | |

| Maximum Cutting Size (45°Quadrate) | 300×180mm | |

| Blade Line Speed | 20~80 m/min | |

| Blade Size | 34×1.1×4550 mm | |

| Blade Guides | Carbide And Bearing Blade Guides | |

| Blade Cleaning | Wire Brush & Flood Coolant | |

| Blade Tension | Manual | |

| Motors | Main Motor | 3kw |

| Hydraulic Motor | 0.75kw | |

| Water pump Motor | 60w | |

| Work Vise Control | Hydraulic+Screw | |

| Machine Size(L×W×H)mm | 2250×2460×1920 | |

| Standard Equipment: | ||

| 1. Blade Cleaning Brush. | ||

| 2. Working Light. | ||

| 3. Roller Table 1pc(2m) | ||

| 4. One Piece Of Bi-metal Saw Blade. | ||

| 5. One Set Of Tools With Tool Box | ||

| 6. Automatic Chip Conveyor | ||

| 7. Bundle Cutting Device | ||

| 8. Inverter | ||

| 9. NC control | ||

| Optional Equipment: | ||

| 1. Extra Common Roller Table | ||

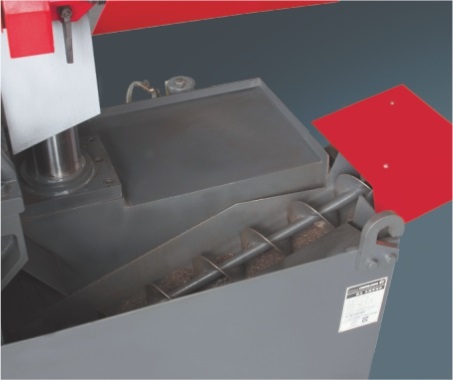

* The Clamping Of This Angle Horizontal Metal Band Saw Machine Is Realized By A Hydraulic Vise. The Maximum Opening Of The Vise Is 400mm. The Oil Cylinder Adopts The Screw Oil Cylinder Method, And The Clamping Stroke Of The Oil Cylinder Is 50mm. When Clamping, The Operator Has to Firstly Move The Movable Vise To About 20mm Away From The Workpiece Through The Manual Screw Rod, Then the clamping can be controlled by the cylinder. The Workpiece Must Be Clamped When Sawing.

* The Feeding Of The Machine Tool Adopts Automatic Feeding. The Feeding Vise Moves Along The Round Guide Rail For Feeding Under The Push Of The Hydraulic Cylinder. The Single Feeding Stroke Is 400mm. The Detection Of The Feeding Length Is Measured By The Grating Ruler.

* The Rotation Of The Machine Tool Is Driven By A Hydraulic Cylinder, And The Angle Measurement Is Controlled By A Rotary Encoder.