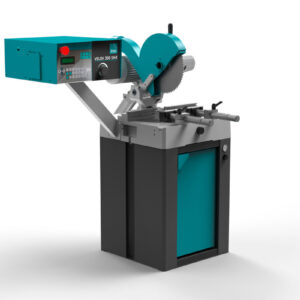

CHENLONG – CH-1000 – Semi Automatic Large Capacity Horizontal Band Saw Machine

Specifications

| Make | CHENLONG |

|---|---|

| Model | CH-1000 |

Description

CHENLONG – CH-1000 – Semi Automatic Large Capacity Horizontal Band Saw Machine

This machine is mainly used for sawing of large forgings, etc.

1. Large Capacity Horizontal Band Saw Machine CH-1000 Is A Semi-Automatic Machine.

2. With Hydraulic Blade Tension

3. Cutting Sizes Of Diameter 1000mm, 1000×1000mm

Specifications

| Product Name | Large Capacity Horizontal Band Saw Machine | |

| Brand | CHENLONG | |

| Model | CH-1000 | |

| Maximum Cutting Size (Round) | 1000mm | |

| Maximum Cutting Size (Quadrate) | 1000×1000mm | |

| Blade Line Speed | 15 to 60 m/min | |

| Blade Size | 67×1.6×9820 mm | |

| Blade Guides | Carbide And Bearing Blade Guides | |

| Blade Cleaning | Wire Brush & Flood Coolant | |

| Blade Tension | Hydraulic | |

| Motors | Main Motor | 11kw |

| Hydraulic Motor | 3.75kw | |

| Water pump Motor | 90w | |

| Work Vise Control | Hydraulic | |

| Machine Size(L×W×H)mm | 4950×2300×2950 | |

| Standard Equipment: | ||

| 1. Blade Cleaning Brush. | ||

| 2. Working Light. | ||

| 3. Roller Table 1pc(2m) | ||

| 4. One Piece Of Bi-metal Saw Blade. | ||

| 5. One Set Of Tools With Tool Box | ||

| 6. Hydraulic Blade Tension | ||

| 7. Inverter | ||

| Optional Equipment: | ||

| 1. Extra Common Roller Table | ||

| 2. Automatic Chip Conveyor | ||

- The Main Drive System Is Consisted Of Gear Reducer, Driving Saw Wheel, Etc. The Gear Reducer Is Directly Connected To The Driving Saw Wheel. It Has Advantages Of Good Rigidity, Low Noise And Stable Transmission. The Main Transmission Adopts Bevel Helical Reducer. The Line Speed Of The Saw Wheels Is Steplessly Adjustable By Inverter.

- The Base Of The Large Capacity Horizontal Band Saw Machine Is Welded By I-beams, High-quality Steel Plates, Etc. After Vibration Aging Treatment, The Welding Deformation Is Small, And It Is Mainly Used To Install Various Parts Of The Machine Tool. The Right End Of The Base Is A Water Tank For Cooling During The Sawing Process.

- There Are Two Types For This Model. Normally The Power Roller Type Machine Is Recommended To Be Used For Sawing Regular Shaped Materials. To Facilitate The Feeding Of The Material, The Machine Tool Adopts Power Roller Table Feeding. The Material Is Placed On The Power Roller Table, By The Pressing The Buttons On The Operation Panel, The Power Roller Table Could Feed The Material Forward Or Backward. The Hydraulic Shuttle Table Type Is Recommended To Cut Irregular Material. The Working Table Of This Type Host Machine Will Be A Hydraulic Shuttle Table, Driven By The Hydraulic Cylinder Under The Table, It Could Feed The Workpiece Forward Or Backward.