Pirtek Southern Highlands, based in Moss Vale, NSW, is dedicated to delivering exceptional fluid transfer solutions. Specialising in mobile onsite service and replacement of hydraulic and industrial hose and fittings, the team proudly serves a diverse customer base.

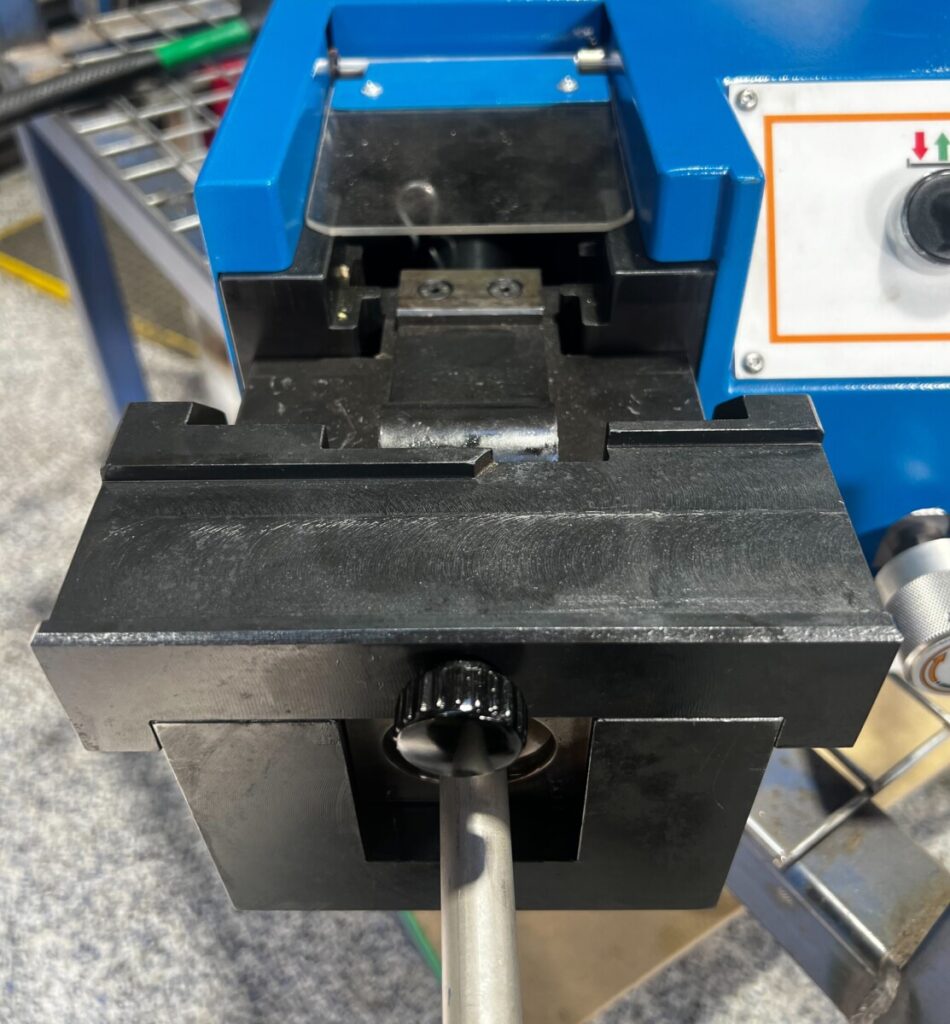

Recently, Stephen Jones, Managing Director at Pirtek Southern Highlands, made a significant investment in another YLM mandrel tube bending machine. This time, purchasing a state of the art machine with CNC capabilities together with a 37 degree flaring machine and deburring machine to enhance their production capabilities. Pirtek Centre Manager Fiona Martin shared they are very appreciative of the Delahenty personalised support, install and training of their new equipment and that “Stephen and all the boys are very excited, and it all looks great. We look forward to what this can do for our business”.

Pirtek’s investment in the impressive YLM CNC mandrel tube bending machine reflects their commitment to building lasting relationships through their consistent delivery of high-quality products and services, ensuring reduced production times and maintaining the superior standards that define strong Pirtek partnerships.

Founded in 1976 by YING HAN Technology Co., YLM is a leading Taiwanese manufacturer known for its CNC, NC, and conventional tube and pipe bending machinery. YLM pioneered the first CNC PC-based controlled tube bender in Asia in 1991.

YLM tube and pipe benders offer a remote control console for operator convenience, foot pedal cycle start for quick and safe loading, and comprehensive safety features including mats, plates, and emergency stops. With integrated gearbox reducers and low-profile bend head designs, these machines ensure smooth and controlled movement, accommodating complex parts with full-capacity feed-through collects. Low decibel production noise enhances operator comfort and shop conditions, while low working heights and multiple axis operations further optimise productivity and safety.

The YLM tube bending machine purchased also features a multi-stack offering numerous bendefits:

Versatility: Multi-stack machines allow for bending tubes at different radii within the same part. This flexibility is essential for complex designs or when you need multiple bends in a single tube.

Efficiency: With multiple stacks, you can perform various bends without changing physical tooling. This reduces downtime and increases productivity.

Precision: Each stack has its own clamp and pressure die, ensuring accurate and repeatable bends. This precision is crucial for consistent results.

Space-Saving: Instead of having separate machines for different bend radii, a multi-stack machine saves floor space and streamlines your production area.

Cost-Effective: While the initial investment may be higher, the long-term benefits in terms of efficiency and versatility make it a cost-effective choice.

Standard YLM CNC benders feature a climate-controlled electrical enclosure to maintain optimal temperature and prolong the life of system components. They incorporate electrical power filtering for stable operation, along with isolated control cabinets to minimise vibration impact on electronics. An oil filtering system with condition indicators protects the supply, while models include a standard radiator-type oil cooler (with optional availability) to regulate oil temperature effectively. Vibration control pads reduce machine movement during operation, complementing a spacious and well-labeled electrical system layout for ease of maintenance and efficient operation.

We invite you to engage with Delahenty Machinery to explore how our innovative solutions can revolutionise your manufacturing operations, driving efficiency and competitiveness in your industry.

About Delahenty Machinery

We are a prominent importer and supplier of machinery solutions for the metal forming, manipulation, and cutting industries. We offer a wide range of top quality machines from some of the top international manufacturers.

Contact us today and experience the best service in the industry.