Founded in 1976, Hilton Manufacturing specialises in precision sheet metal manufacturing and has a longstanding commitment to investing in lean manufacturing capabilities to maintain its global competitiveness.

Recently, Delahenty Machinery has entered into a partnership with Hilton to implement a Kassow robotic sanding solution aimed at further enhancing their lean manufacturing culture. This strategic investment is designed to streamline production processes, thereby ensuring cost competitiveness through reductions in labor costs, physical footprint, running expenses, and supplier response times.

The Kassow 7-axis collaborative robot, renowned for its extended range of motion and superior task accuracy, has been selected for its suitability in industrial sanding applications. Delahenty Machinery’s proposed cobot sanding solution includes the versatile OnRobot electric orbital sander, capable of accommodating various part geometries to ensure consistent and high-quality finishes. The integration of OnRobot’s grit changer enables automated switching between different sanding discs, minimising downtime and reducing reliance on manual labor.

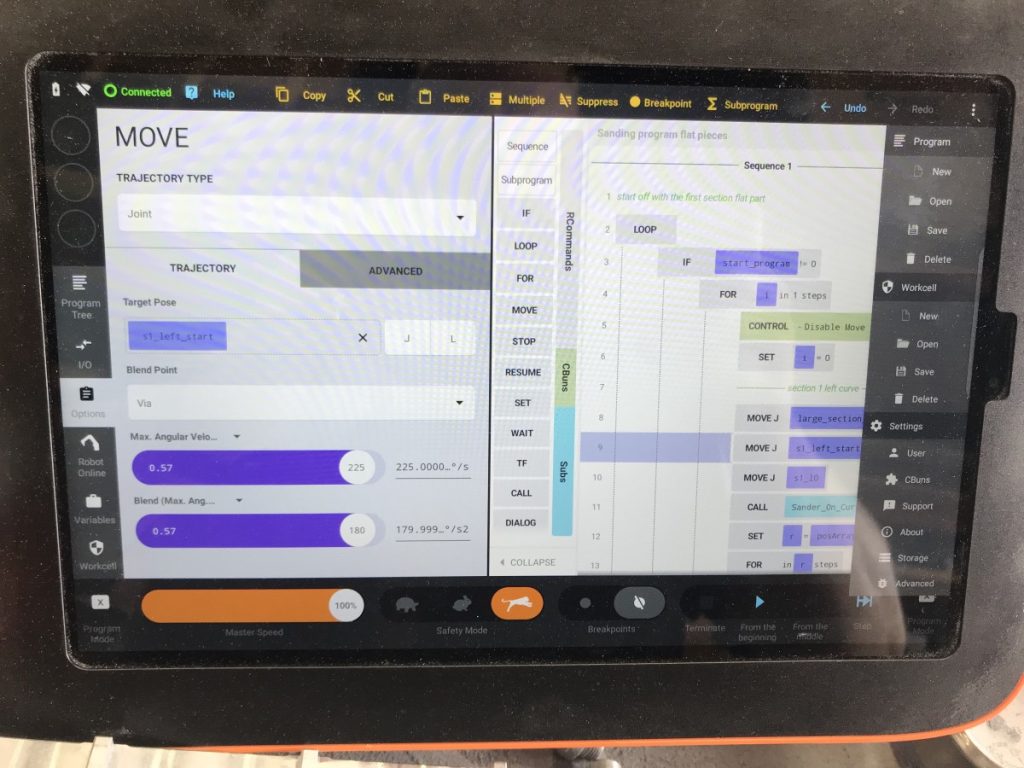

The key feature of our KASSOW robots is the intuitive user interface. The modern-tablet based interface is using all benefits of the powerful Android System to help users build their applications.

- Split screen concept

- Block based programming

- Optimised for robot applications

- Responsive and intuitive environment

- Dynamic content support, native 3D engines

The OnRobot Sander offers a comprehensive solution for surface finishing with a setup that is both fast and simple, reducing the complexity associated with material removal tasks. This powerful and durable electric sander operates without requiring compressed air, which significantly lowers both running and maintenance costs. The solution included a cost-effective Grit Changer that allows for automatic switching between sanding grits without operator intervention, thereby improving efficiency. Its versatility allows it to handle a wide range of part geometries and materials, while its sensing capabilities ensure precise adaptation to surface variations or part misalignment. This enhances product quality and consistency, reducing scrap. Additionally, the sander minimises operator fatigue and hazards, making it easier to comply with local health and safety regulations.

Moreover, the initiative underscores a commitment to employee engagement and safety. By leveraging robotic automation, the project aims to mitigate workplace injury risks associated with high vibration from traditional hand tools and exposure to fine dust particles.

We invite you to engage with Delahenty Machinery to explore how our innovative robotic automation solutions can revolutionise your manufacturing operations, driving efficiency and competitiveness in your industry.