Delahenty Machinery has a proud history of partnering with Australian owned and operated businesses. Earlier this year the Delahenty team finalised the installation of a new YING HAN CNC38 rolling and tube bending machine for Jayco’s caravan corner molds.

Established in 1975, the Jayco Corporation is Australia’s leading RV manufacturer and is one of the nation’s most iconic brands of recreational vehicles that are recognised for quality and affordability. A locally owned family business employing more than 1,000 employees, Jayco specialises in designing, manufacturing, and distributing a wide range of RVs, including Camper Trailers, Pop Tops, Caravans, Campervans and Motorhomes.

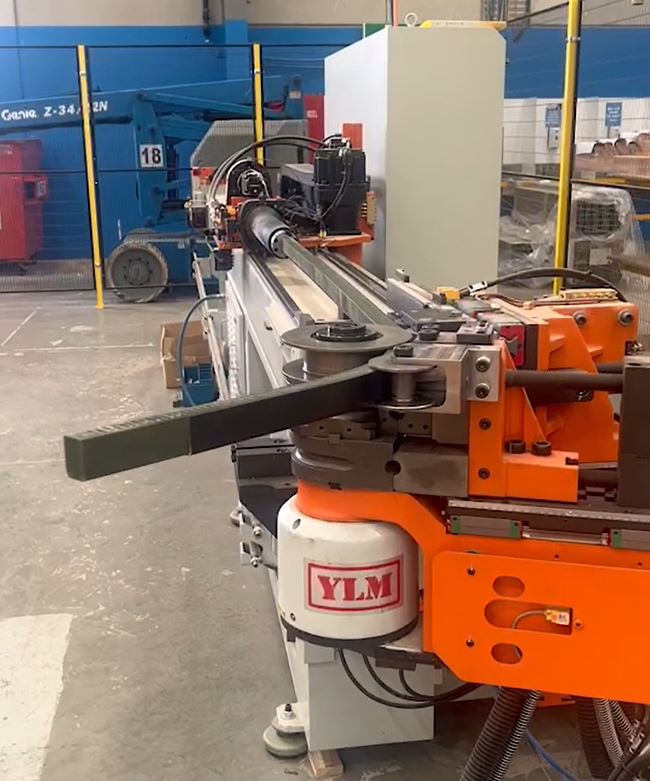

Jayco presented a unique challenge to the Delahenty team who worked on a solution requiring two formed radius that can be performed in a single process on the one machine. The new YLM CNC38 multi stack, multi axis tube bending machine made in Tawain, was chosen to be customised with rolling functionality to support manual bending of aluminium profiled extrusions rather than common draw bending.

The machine is now capable of a broad range of purposes including ring rolling and tube bending of various ratios and provides great flexibility when bending tube, square or customised extrusions.

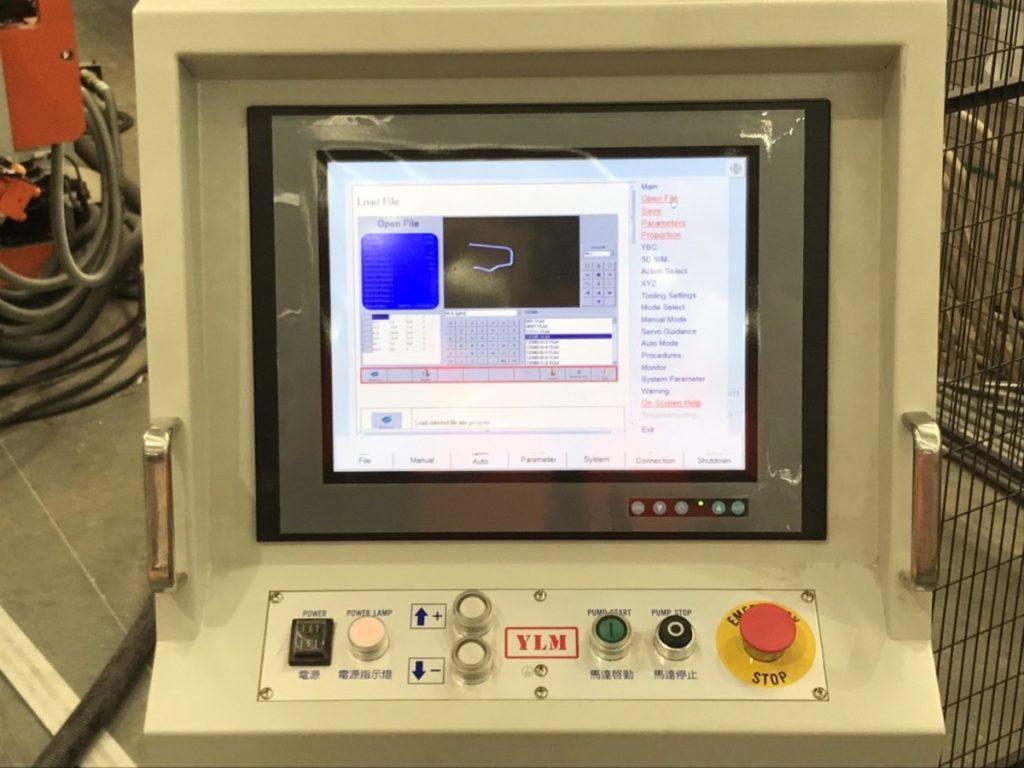

The Delahenty technicians recently completed a comprehensive education session with the Jayco team on the machines draw and push roll bending functions, how the multiple axis works simultaneously to decrease bending cycle time, and how to use the batch work functions just to list a few.

The team was impressed with the production cycle time, the user-friendly program setup and the ease of upgrading and modifying programs using the PC base controlled system.

Michael McCarthy of Delahenty Machinery commented that “the flexible YLM rolling and tube bending machine will complement Jayco’s state-of-the-art manufacturing facilities and ensure the highest standards of quality, safety, and craftsmanship in the production of its recreational vehicles. Jayco will benefit significantly from cost and time savings as this process had been previously outsourced”.

Whether you’re a small or a large manufacturer, Delahenty Machinery have a tube bending solution that will meet your specific needs.

We invite you to contact the Delahenty team and explore metal manipulation options to improve your business operations.

View Product: YLM – CNC Hybrid Tube Bending Machine – CNC-38MS-5A (delahenty.com.au)

#YLMCNC38MS #hybridtubebender #precisionbending #highproductivity #tubesandpipes #metalfabrication #efficientmanufacturing #constructionequipment #delahentymachinery #YLM