Capral Aluminium, a premier extruder and distributor of aluminium products in Australia, has enhanced its in-house capabilities by acquiring the advanced COMAC Profile Bending Machine Model 304 HV. This purchase includes several sets of custom tooling designed for unique extrusion needs, all crafted in Delahenty Machinery’s toolroom in Knoxfield, Victoria. This new addition reinforces Capral’s commitment to delivering top-tier aluminium systems and services.

As Australia’s largest provider of aluminium extrusions and products, Capral Aluminium is renowned for its extensive range of industry-leading systems for both built environments and industrial applications. Capral’s portfolio includes high-quality solutions for the automotive industry as well as windows, doors, framing, security, and curtain walls, as well as light fabrication systems, fencing, shower and robe systems, fixed louvres, and sunshades. With a focus on innovation, Capral’s products are crafted to meet the diverse needs of commercial, residential, and security applications.

COMAC Profile Bending Machine Model 304 HV: Key Features and Specifications

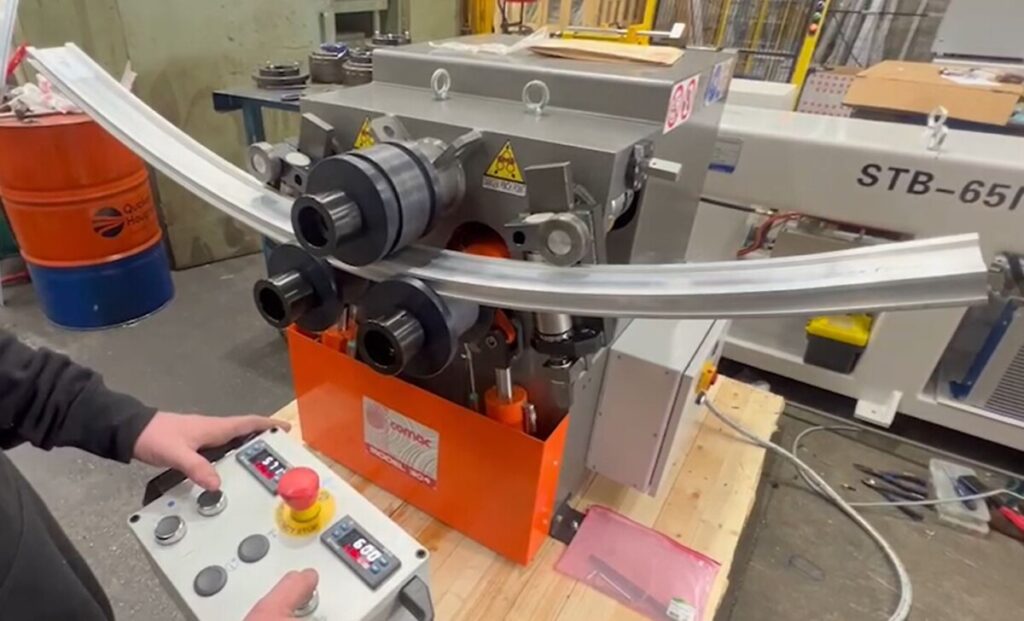

- Three Driving Rolls: Ensures consistent and reliable bending.

- Independent Hydraulic Adjustment: Allows for precise pre-bending of both the leading and trailing edges of profiles.

- Lateral Guide Rolls: Offer three-directional movement (axial, radial, angular) with mechanical adjustment for enhanced accuracy.

- Digital Readouts: Provide 0.25 mm accuracy for precise roll positioning.

- Remote Control Console: Operates the machine via a free-standing console for ease of use.

- Horizontal-Vertical Working Position: Provides flexibility in bending orientations.

Capral Manufacturing Supervisor Suresh Madambath confirmed that the machine was simple to program, easy to operate and durable. Suresh shared that the business was looking forward to the cost benefits of bringing the bending in house but also excited about the opportunity of expanding the business in new areas for income generation.

Capral’s new COMAC Profile Bending Machine is known for its’ versatile three-roll bending designed to handle a variety of aluminium profiles and tubes with precision and flexibility. This model features a double initial pinch style with a stationary upper roll and independently adjustable lower rolls, making it ideal for a wide range of bending tasks.

Construction and Durability

- High-Quality Roll Shafts: Made from Nickel Chromium Molybdenum alloyed steel, induction hardened to 62-64 HRC for durability and precision.

- Modular Bending Rolls: Heat-treated to 60 HRC, ensuring long-term wear resistance.

- Adjustable Slip Clutch: On the upper roll, this feature accommodates different peripheral speeds for smoother operation and enhanced bending accuracy while protecting the machine from overloads.

- Robust Gear Journals and Transmission: Features involute spline gears and an electro-mechanical drive with AC motor, reduction gearbox, and chain.

- Steel Frame and Gearbox: The machine frame is constructed from fabricated and machined steel plate with an oil bath-lubricated helical reduction gearbox.

- Enclosed Hydraulic Unit: Protected by overload relief valves and driven by a dedicated AC motor, with check valves on hydraulic cylinders to maintain roll positions under load.

Bending Capacities

- Nominal Capacity: Modulus of inertia S = 3.5 cm³, suitable for various bending applications.

With the addition of the COMAC Profile Bending Machine Model 304 HV, Capral Aluminium continues to lead the industry in providing high-quality, versatile aluminium solutions, enhancing its ability to meet the evolving needs of its clients with greater precision and efficiency.