Are you planning to use a Ball mandrel and Wiper die to bend the pipe but do not know the process?

Here is the guide to bending tubes with ball mandrel and wiper die.

Why Use a Ball Mandrel and Wiper Die to Bend Tubing?

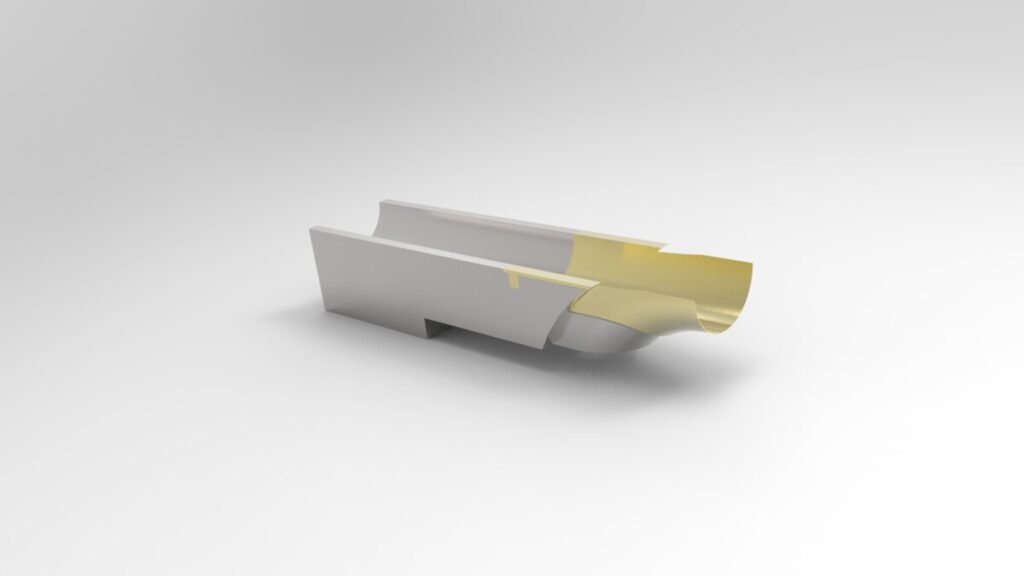

One of the oldest methods for bending tubing is using a ball-mandrel and Wiper die. A wiper die has a stationary wiper that wipes the ball as it rolls against it, making a near-perfect radius every time. This will ultimately help improve the bend quality of your bends.

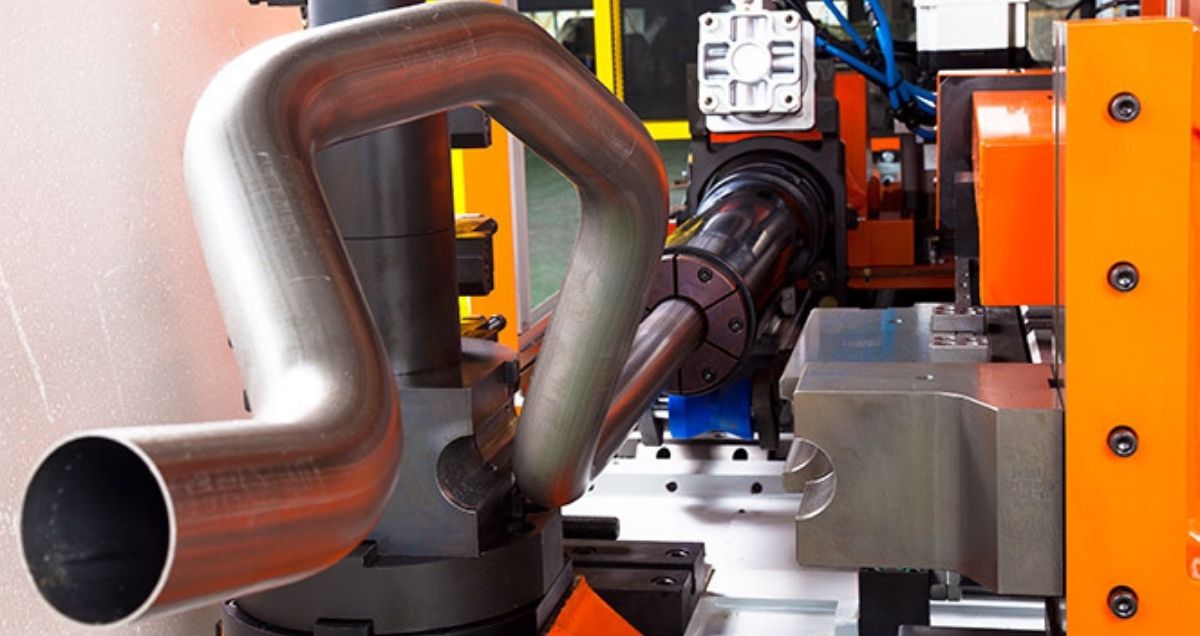

A ball mandrel supports the tube throughout the tube bending process and is used to produce flares, tees, and reducers. The ball-end reduces friction and oxidation during bending, allowing the workpiece to be held in a tight radius while not marring the surface or allowing distortion. The result is precise bending that produces better flare control and dimensional consistency.

How to Bend Tubing with a Ball Mandrel and Wiper Die

Firstly, you must make a successful plan to bend the tube with a ball mandrel and wiper die. You need to consider the material you are going to bend. Try to source the entire material from one supplier. It will help in maintaining the consistency of the tubing dimensions and characteristics.

Start considering the machines you are going to use. The bending machine should be in the right condition and should have good quality because poor quality tooling leads to longer set-up times, more scrap, poorly bent tubes, and unacceptable bends. You need an experienced one to operate that machine.

When performing this type of bend, the piece of tooling, the Wiper Die should be accurate. The groove must be slightly larger than the O.D. of the tube ñ 10% of wall thickness as being minimum. It must be of high polish lubricated with thin oil. Too much fat or too heavy oil in this area will cause wrinkles. Wiper Dies fit to bend die groove must be 85% contact from 12:00 o’clock to 6:00 and for at least 15-20 degrees back from tangent. When the bend die does not support the Wiper Die. It will spring away from the mandrel. It can cause the tube to wrinkle.

Wrapping Up

These tools are excellent aids for bending tubing. It allows you to make consistent tapers on tubing, whether you want a tight or loose fit. The mandrels and dies will enable you to make different-sized bends and give you those custom curves that your other tools do not allow.

Delahenty Machinery is a leading manufacturer of tube bending machinery, Wiper dies, and ball mandrels. Many industries use our machines to process tubes and pipes, from ultra-pure copper and brass to hardened steel, stainless steel, aluminum, and titanium. Contact us for more details.